Page 108 - Pressure Vessel Design Manual

P. 108

General Design 89

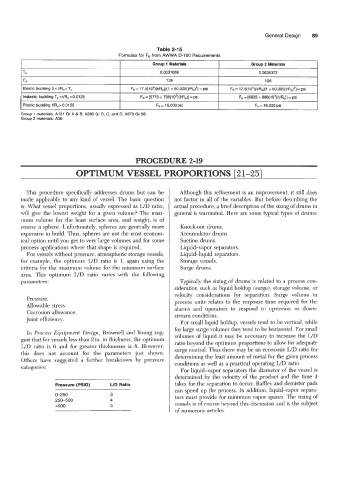

Table 2-15

Formulas for Fb from AWWA D-100 Requirements

Group 1 Materials Group 2 Materials

Tc 0.0031088 0.0035372

CC 138 126

Elastic buckling 0 e t/R, e T, Fb= 17.5(lO5)(VR,)[(I +50,000(t/R0)*]=psi Fb= 17.5(lO5)(VRO)[1 +50,000(L'R,)2] =psi

Inelastic buckling T, c VR, e 0.01 25 Fb = [5775 + 738(103)(VRo)] = psi Fb = [6925 + 886(103)(t/R,)] =psi

Plastic buckling t/Ro> 0.0125 Fb = 15,000 psi Fb = 18,000 psi

Group 1 materials: A131 Gr A & B; A283 Gr B. C, and D; A573 Gr 58.

Group 2 materials: A36.

PROCEDURE 2-19

OPTIMUM VESSEL PROPORTIONS 121-251

This procedure specifically addresses drums but can be Although this refinement is an improvement, it still does

made applicable to any land of vessel. The basic question not factor in all of the variables. But before describing the

is: What vessel proportions, usually expressed as UD ratio, actual procedure, a brief description of the sizing of drums in

will give the lowest weight for a given volume? The maxi- general is warranted. Here are some typical types of drums:

mum volume for the least surface area, and weight, is of

course a sphere. Unfortunately, spheres are generally more Knock-out drums.

expensive to build. Thus, spheres are not the most econom- Accumulator drums.

ical option until you get to very large volumes and for some Suction drums.

process applications where that shape is required. Liquid-vapor separators.

For vessels without pressure, atmospheric storage vessels, Liquid-liquid separators.

for example, the optimum LJD ratio is 1, again using the Storage vessels.

criteria for the maximum volume for the minimum surface Surge drums.

area. This optimum LJD ratio vanes with the following

parameters: Typically the sizing of drums is related to a process con-

sideration such as liquid holdup (surge), storage volume, or

velocity considerations for separation. Surge volume in

Pressure. process units relates to the response time required for the

Allowable stress. alarms and operators to respond to upstream or down-

Corrosion allowance. stream conditions.

Joint efficiency.

For small liquid holdup, vessels tend to be vertical, while

for large surge volumes they tend to be horizontal. For small

In Process Equipment Design, Brownell and Young sug- volumes of liquid it may be necessary to increase the L/D

gest that for vessels less than 2 in. in thickness, the optimum ratio beyond the optimum proportions to allow for adequate

LJD ratio is 6 and for greater thicknesses is 8. However, surge control. Thus there may be an economic UD ratio for

this does not account for the parameters just shown. determining the least amount of metal for the given process

Others have suggested a further breakdown by pressure

categories: conditions as well as a practical operating UD ratio.

For liquid-vapor separators the diameter of the vessel is

determined by the velocity of the product and the time it

Pressure (PSIG) LID Ratio takes for the separation to occur. Baffles and demister pads

can speed up the process. In addition, liquid-vapor separa-

0-250 3 tors must provide for minimum vapor spaces. The sizing of

250-500 4

>500 5 vessels is of course beyond this discussion and is the subject

of numerous articles.