Page 103 - Pressure Vessel Design Manual

P. 103

84 Pressure Vessel Design Manual

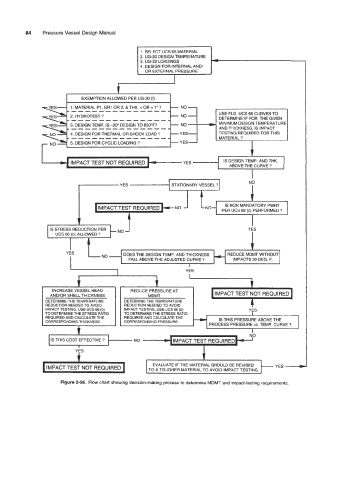

1. SELECT UCS 66 MATERIAL

2. UG-20 DESIGN TEMPERATURE

3. UG-22 LOADINGS 4

4. DESIGN FOR INTERNAL AND/

OR EXTERNAL PRESSURE

______----------

- NO- USE FLG. UCS 66 CURVES TO

DETERMINE IF FOR THE GIVEN

------ ---------- N - V MINIMUM DESIGN TEMPERATURE

- 0

AND THICKNESS, IS IMPACT

4. DESIGN FOR THERMAL OR SHOCK LOAD ? -YES- TESTING REQUIRED FOR THIS

c--------------- MATERIAL ?

I

'rr"

rYES

NO

1

STATIONARY VESSEL ?

I

YES

YES DOES THE DESIGN TEMP. AND THICKNESS REDUCE MDMT WITHOUT

FALL ABOVE THE ADJUSTED CURVE ? IMPACTS 30 DEG. F.

I

YES

AND/OR SHELL THICKNESS

DETERMINE THE TEMPERATURE DETERMINE THE TEMPERATURE

REDUCTION NEEDED TO AVOID REDUCTION NEEDED TO AVOID

IMPACT TESTING, USE UCS 66 (b) IMPACT TESTING, USE UCS 66 (b) YES

TO DETERMINE THE STRESS RATIO TO DETERMINE THE STRESS RATIO

REQUIRED AND CALCULATE THE REQUIRED AND CALCULATE THE IS THIS PRESSURE ABOVE THE

CORRESPONDING PRESSURE.

PROCESS PRESSURE vs. TEMP. CURVE ?

J

1

IS THIS COST E

-

EVALUATE IF THE MATERIAL SHOULD BE REVISED YES __I

TO A TOUGHER MATERIAL TO AVOID IMPACT TESTING

Figure 2-56. Flow chart showing decision-making process to determine MDMT and impact-testing requirements.