Page 176 - Pressure Swing Adsorption

P. 176

I I

150 PRESSURE SWING ADSORPTION EQUILIBRIUM THEORY 151

Thus, the net effect of ternoerature shifts during this four-steo cycle is PSA WITH INCREASING PRESSURE

positive. That 1s, the recovery of the light component should be somewhat

greater when the natural temperature shifts occur than if the system were

forced to remam isothermal. The net effect IS expected to be mmor since, 40

according to the basis chosen, only the ourge and feed streams are affected,

and the mcrease of the ourge stream should be small relative to the decrease

of the feect ·stream. 35

u

Before leaving this subject, 1t is worthwhile to point out that the conclu-

sion Just reached 1s not general: different cycies will resoonct to temperature w

shifts differently. For example, for cycies in which the heavy component is a: 30

::,

oroctuced durmg blowdown (cf. Section 4.4.5), the most imoortant stream m f-

<(

determmmg recovery is the blowdown step. This steo involves a large a:

w

temoerature drop (relative to the pressurization, high-pressure oroduct, and CL 25

:,:

w

rinse steps) due to desorption and depressunzatlon. As can be seen from EQ. I-

4.41, the net effect ·is that the adsorbent retains more of the heavy component 20

than 1t would under isothermal conditions (i.e .• the magmtude of the second

term on the right-hand side is larger), so recovery is diminished.

Aside -from gaining a better understanding of PSA systems via their 15

inherent thermal response, there is an even greater mcent1ve to understand 10 20 30 40 50 60 70

this behavior. To elaborate, in many PSA systems 1t is important to orevent TIME (s)

complete breakthrough, (e.g., durmg feed and cocurrent blowdown steps),

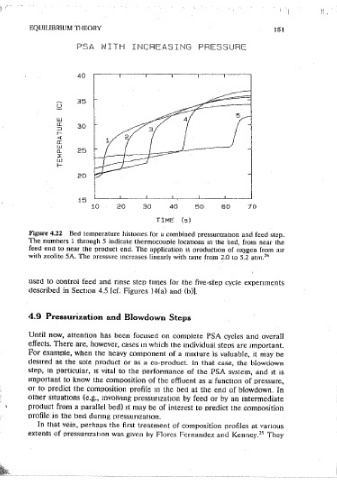

which would reduce the purity of the product. Conversely, if breakthrough IS Figure 4.22 Bed temperature histones for a combined pressunzauon and feed step.

not imminent at the end of these steps, the product recovery cannot be as The numbers 1 through 5 indicate thermocoupie locations m the bed, from near the

high as possible, smce any purified gas left m the column 1s exhausted with feed end to near the product end. The application is oroduttmn of oxygen from a1r

with zeolite 5A. The pressure mcreases linearly with ume from ~.O to 5.2 atm. 26

the byproduct. Simiiariy, a rmse step should be allowed to proceed until

breakthrough is Just como1ete. To go further would reduce recovery, and to

stop prematurely would reduce ourity. Accordingly, both high product punty used to control feed and rinse step times for the five-step t.')'cle experiments

and high-recovery PSA performance can be achieved by termmatmg such described in Section 4.5 lcf. Figures 14(a) and (b)].

steos very precisely. A minor problem ts that many comoosit1on sensmg

instruments have long response times or large samole volumes, so that

on•line measurements are often unpractical. That is where the thermal 4.9 Pressurization and Blowdown Steps

response comes m,

The fact · that the shock wave of temperature usually comcides with the Until now, attention has been focused on comoJete PSA cycies and overall

composition front' can be exoloited to control the t1mmg. Evidence for that is effects. There are, however, cases in which the individual steps are important.

shown both m Figure 4.20, which was described oreviousiy, and m Figure For example, when the heavy component of a mixture )s valuable, it may be

4.22, in which, again, oxygen 1s being separated from air. In the iatter figure, des1red as the sole product or as a co-oroduct. In that case, the blowdown

the pressure increases from 2.0 to 5.2 atm. as feed 1s being admitted to and step, in particular, 1s vitai to the performance of the PSA svstem, and 1t 1s

product is bemg slowly released from the column. As can be seen, the important to know the comoosition of the effluent as a: function of pressure,

average temperature m the bed rises, but the sharpness and magmtude of the or to predict the composition profile m the bed at the end of blowdown. In

temperature front are essentially the same as when pressure was constant. other s1tuat1ons (e.g., mvolvmg pressunzat10n by feed or by an intermediate

26

Eqmvaient, but reverse effects occur when the bed pressure decreases. The product from a parallel bed) 1t may be of interest to oredict the composition

possibility of controlling the step times in this manner can orevent reduced profile in the bed dunng pressunzatwn.

recovery [e.g., due to diminished adsorbent capacity or when operatmg Jn that vein, perhaps the first treatment of composition profiles at various

conditions (or ambient conditions) vary significantly]. Jn fact, this concept was extents of pressurization was given hy Flores Fcrn;ndez and Kenney. 25 They