Page 210 - Pressure Swing Adsorption

P. 210

n

l 11,

I,

'

186 PRESSURE SWING ADSORPTION DYNAMIC MODELING OF A PSA SYSTEM 187

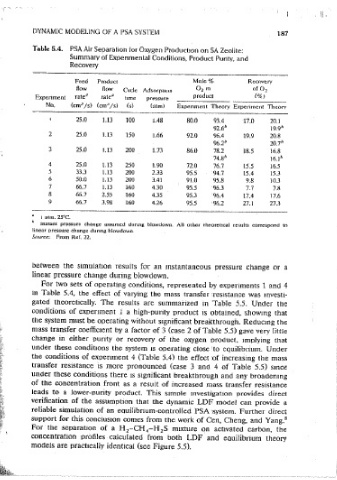

Table 5.3. Kinetic and Equilibrium Data and Other Common Table 5.4. PSA Air Separation for Oxygen Production on SA Zeolite;

Parameter values Used in the Simulations of PSA Air Summary of Expenmental Conditions, Product Purity, and

Separation for Oxygen Production Recovery

Feed composilion 21% oxygen, 79% nitrogen Mole%

Adsorhen( Linde 5A zeolile Feed Product Recovery

How flow Cvcle Adsorp11on 0 2 m of 0

Bed length (cm) 35.0 ratea rate 11 product (%) 2

Bed radius (cm) 1.75 ' Expenment time pressure

i

No.

I

Particle diameter (cm) 0.0707 I (cm' /s) (cm.; /s) (s) (aim) Experiment Theory Experiment Theorv

Bed void8ge 0.40 25.0 1.13

Amhient temperature (°C) 25.0 I 100 l.48 80.0 93.4 17.0 20.1

Blowdown pressure (atm) l.0 2 25.0 1.13 92.6b 19.9"

Purge pressure (atm) l.07 ± 0.05 I 150 I.66 92.0 96.4 19.9 20.8

I

Peclet number 500.0 ' 3 25.0 96.2/, 20.71>

Dur:it1on of s1ep I or 3 0.3 of total cvc\e trme ! . i. 13 200 1.73 86.0 78.2 18.5 16.8

Duration of step 2 or 4 0.2 of total cvcle time 1 4 74.8h 16.1 11

I

Equilibrium constant l 5 25.0 l.13 250 1.90 72.0 76.7 15.5 16.5

33.3

1.13

200

for oxygen (KA) 4.1° ! 2.33 95.5 94.7 15.4 15.3

6 50.0 1.13 200 3.41 91.0 95.8 9.8 10.3

Equilibnum constant

7 66.7 1.13 160 4.30 95.5 96.3 7.7 7.8

for nitrogen (K ) 14.8°

8 8 66.7 2.55 160 4.35 95.3 96.4 17.6

LDF constant for 9 66.7 3.98 17.4

1

oxygen (kA)(s- ) 62.0 (at I atm)b 160 4.26 95.5 96.2 27.1 27,3

LDF constant for I atm. 25°C.

nitrogen (k ) (s- 1 ) 19.7(at I atm)b

8 lnsiant pressure change assumed durmg blowdown. All other 1heoret1cal results correspond to

Satui-alion consrant for

linear pressure change dunog hlowdown

oxygen (q AS) (mol/cm·') 5.26 X 10-Jc Srmrce: From Ref. 22.

Sa1ura11on constant for

3

nitrogen (q 85 ) (mol/cmJ) 52.6 X 10- J

52

Chromatographic data (dimens10nless) (Boniface ). between the s1muJat1on results for an instantaneous pressure change or a

1, Molecular diffusion control, tonuos1ty factor= 3.0 and particle porosnv = linear pressure change during blowdown.

0.33; all expenmental conditions are within the iarge-cycle-time region, for

which n approaches the GluecJrnuf limn of 15. For two sets of operating conditions, represented t,y experiments 1 and 4

Miller et al.j 3 m Table 5.4, the effect of varying the mass transfer Tes1stance was investi-

J Since oxygen and nitrogen molecules are about the same size, their sarura- gated theoretically. The results are summarized in Table 5.5. Under the

11011 capaci1ies are assumed to be 1he .same.

conditions of expenrnent 1 a high-purity product is obtained, showmg that

the system must be operating without significant breakthrough. Reducing the

mass transfer coefficient by a factor of 3 (case 2 of Table 5.5) gave very little

together with the theoretically predicted values from the numerical simula- change in either punty or recovery of the oxygen t>roduct. 1rnolying that

tion. The mole fraction of oxygen m the product refers to the average oxygen under these conditions the system 1s operating close 'to eauilibnum. Under

concentration in the product at steady state. The theoretical oxygen concen- the conditions of expenment 4 (Table 5.4) the effect of increasing the mass

tration m the product at steady state was therefore computed at short transfer resistance is more pronounced (case 3 and 4 of Table 5.5) smce

mtervals anct was integrated to detennine the average. Since the product rate under these conditions there 1s significant breakthrough and any broadening

rather than the purge rate was fixed, the recovery calculation was straightfor- of the concentration front as a resuit of increased mass transfer resistance

ward. The-effects of cycle time, adsorption pressure, and product withdrawal leads to a lower-purity product. This s1moie mvestigat1on provides direct

rate on the purity and recovery are shown m Figure 5.4. It is evident that the verification of the assumption that the dynamic LDF modei can provide a

theoretical moctei gives a reasonably accurate prediction of both the ounty reliable simulation of an eauilibnum-controlled PSA ·system. Further direct

and recovery of the oxygen product over the range of exoenmental values support for this conctusmn comes from the work of Cen, Cheng, and Yang. 8

examined. For the separation of a H -CH -H S mixture on activated carbon, the

2

4

2

The effect of varymg the blowctown conditions was also tnvestlgated and concentration profiles caicuiated from both LDF and eauilibrium theory

the results are shown m Figure 5.4(a). There 1s clearly very little difference models are oract1cally identical (see Figure 5.5).