Page 137 - Principles of Catalyst Development

P. 137

CATALYST PREPARATION 125

Each step in the recipe must be translated into large-scale operation.

First, each must be technically feasible, that is, engineering counterparts

must exist for laboratory procedures. Equipment is usually no

problem, (35,160) but maintaining the controlling conditions may be, Second,

scale-up must be economical. The most important factor here is capital

investment to acquire facilities for what may be large quantities. Purity

levels of reagents is another issue which requires attention. Large quantities

of very pure feedstocks may be expensive or even unattainable.

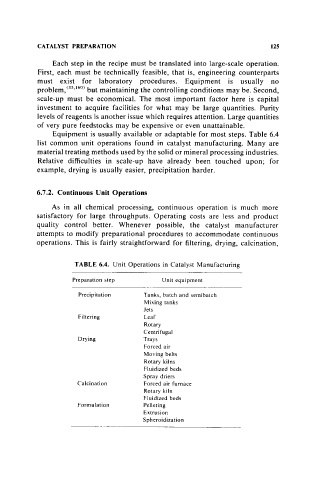

Equipment is usually available or adaptable for most steps. Table 6.4

list common unit operations found in catalyst manufacturing. Many are

material treating methods used by the solid or mineral processing industries.

Relative difficulties in scale-up have already been touched upon; for

example, drying is usually easier, precipitation harder.

6.7.2. Continuous Unit Operations

As in all chemical processing, continuous operation is much more

satisfactory for large throughputs. Operating costs are lless and product

quality control better. Whenever possible, the catalyst manufacturer

attempts to modify preparational procedures to accommodate continuous

operations. This is fairly straightforward for filtering, drying, calcination,

TABLE 6.4. Unit Operations in Catalyst Manufacwring

Preparation step Unit equipment

Precipitation Tanks, batch and semi batch

Mixing tanks

Jets

Filtering Leaf

Rotary

Centrifugal

Drying Trays

Forced air

Moving belts

Rotary kilns

Fluidized beds

Spray driers

Calcination Forced air furnace

Rotary kiln

Fluidized beds

Formulation Pelleting

Extrusion

Spheroidization