Page 140 - Principles of Catalyst Development

P. 140

128 CHAPTER 6

cylindrical cavity as shown and a piston applies prescribed pressures. Values

from 10 to 4 X 103 atmospheres are common, depending upon the compress-

2

ibility properties of the powder. Grains must be deformable since boundaries

flow together to produce the finished pellet. Factors such as the ultimate

tensile strength of the materials, mesoporosity of the grains, and moisture

content are important. Some materials, such as kieselguhr, pellet easily,

others require assistance from the addition of small amounts of plasticizers

and lubricants. Graphite, talc, and stearic acid are used for this purpose. IJS)

The pellet is ejected after compression. It is very uniform in shape and

dimensions, has high mechanical strength and moderate porosity. Fibers

are sometimes added, for example, polymers, that are burned off to increase

macro porosity, and metals, to improve thermal conductivity in or out of

the pellet.

Pelletization is the most expensive method. For continuous production,

complicated disk-type rotating cylinders with staggered pistons are used.

Complexity of these movements, stress on metal parts due to high pressures,

and presence of abrasive powders all contribute to high equipment and

maintenance costs. For a given throughput, larger pellets are generally

cheaper to make.

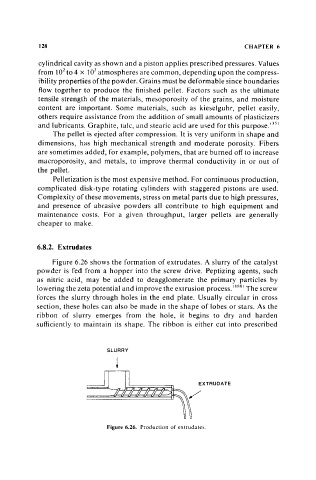

6.8.2. Extrudates

Figure 6.26 shows the formation of extrudates. A slurry of the catalyst

powder is fed from a hopper into the screw drive. Peptizing agents, such

as nitric acid, may be added to deagglomerate the primary particles by

lowering the zeta potential and improve the extrusion process. (I RR) The screw

forces the slurry through holes in the end plate. Usually circular in cross

section, these holes can also be made in the shape of lobes or stars. As the

ribbon of slurry emerges from the hole, it begins to dry and harden

sufficiently to maintain its shape. The ribbon is either cut into prescribed

SLURRY

EXTRUDATE

Figure 6.26. Production of extrudates.