Page 143 - Principles of Catalyst Development

P. 143

CATALYST PREPARATION 131

HEATED HYDROGEL

AIR

~

DRYING CHAMBER

MICROSPHERES

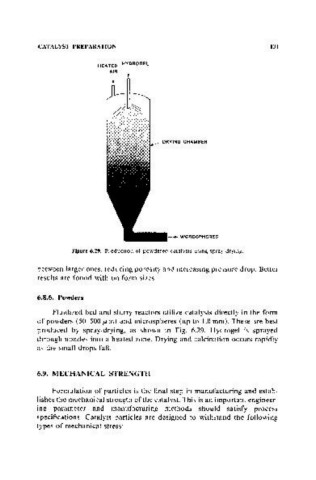

Figure 6.29. Production of powdered catalysts using spray drying.

between larger ones, reducing porosity and increasing pressure drop. Better

results are found with uniform sizes.

6.8.6. Powders

Fluidized bed and slurry reactors utilize catalysts directly in the form

of powders (50-500 IA-m) and microspheres (up to 1.0 mm). These are best

produced by spray-drying, as shown in Fig. 6.29. Hydrogel is sprayed

through nozzles into a heated zone. Drying and calcination occurs rapidly

as the small drops fall.

6.9. MECHANICAL STRENGTH

Formulation of particles is the final step in manufacturing and estab-

lishes the mechanical strength of the catalyst. This is an important engineer-

ing parameter and manufacturing methods should satisfy process

specifications. Catalyst particles are designed to withstand the following

types of mechanical stress: