Page 144 - Principles of Catalyst Development

P. 144

132 CHAPTER 6

6.9.]. Abrasion During Transit

Abrasion is loss of material due to contact of particles with container

walls. Commercial catalysts are shipped to customers in metal, plastic, or

fiber drums containing up to 250 kg. Polyethylene liners or bags are often

used. Inert blanketing is usually not necessary. Drums are transported by

train or truck, handled by fork-lift in and out of storage, and lifted to the

top of reactors with cranes. Care must be taken to avoid excessive shaking,

rolling, dropping, or other mishandling during these operations. Drums

should not be exposed to inclement weather conditions. It is advisable to

use special rigs for effective movement of the drums, as recommended by

the manufacturer.

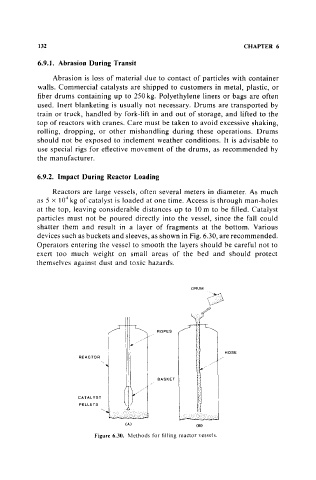

6.9.2. Impact During Reactor Loading

Reactors are large vessels, often several meters in diameter. As much

as 5 x 10 kg of catalyst is loaded at one time. Access is through man-holes

4

at the top, leaving considerable distances up to 10 m to be filled. Catalyst

particles must not be poured directly into the vessel, since the fall could

shatter them and result in a layer of fragments at the bottom. Various

devices such as buckets and sleeves, as shown in Fig. 6.30, are recommended.

Operators entering the vessel to smooth the layers should he careful not to

exert too much weight on small areas of the bed and should protect

themselves against dust and toxic hazards.

DRUM

ROPES

I

t/

REACTOR I HOSE

BASKET

CATALYST

PELLETS

(A)

(B)

Figure 6.30. 1\1ethods for filling reactor vessels.