Page 156 - Principles of Catalyst Development

P. 156

144 CHAPTER 7

HYDRAULIC

PRESS

CATALYST

PELLET

(a) (b)

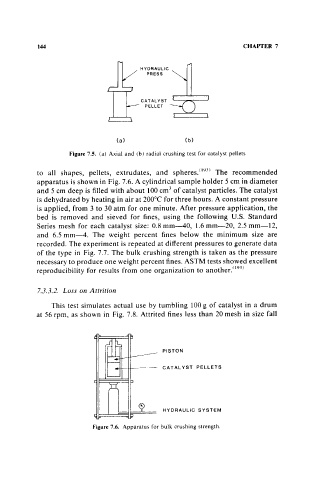

Figure 7.5. (a) Axial and (b) radial crushing test for catalyst pellets

to all shapes, pellets, extrudates, and spheresY93) The recommended

apparatus is shown in Fig. 7.6. A cylindrical sample holder 5 cm in diameter

and 5 cm deep is filled with about 100 cm of catalyst particles. The catalyst

3

is dehydrated by heating in air at 200°C for three hours. A constant pressure

is applied, from 3 to 30 atm for one minute. After pressure application, the

bed is removed and sieved for fines, using the following U.S. Standard

Series mesh for each catalyst size: 0.8 mm-40, 1.6 mm-20, 2.5 mm-12,

and 6.S mm-4. The weight percent fines below the minimum size are

recorded. The experiment is repeated at different pressures to generate data

of the type in Fig. 7.7. The bulk crushing strength is taken as the pressure

necessary to produce one weight percent fines. ASTM tests showed excellent

reproducibility for results from one organization to another.(J93)

7.3.3.2. Loss on Attrition

This test simulates actual use by tumbling 100 g of catalyst in a drum

at 56 rpm, as shown in Fig. 7.8. Attrited fines less than 20 mesh in size fall

PISTON

CATALYST PELLETS

HYDRAULIC SYSTEM

Figure 7.6. Apparatus for bulk crushing strength.