Page 190 - Principles of Catalyst Development

P. 190

178 CHAPTER 7

extended experimental runs to return to some standard experimental condi-

tion at the end of the run. If results are the same, this ensures that no

deactivation has taken place. If activity has declined, then measured rates

may be "corrected" back to the fresh state.

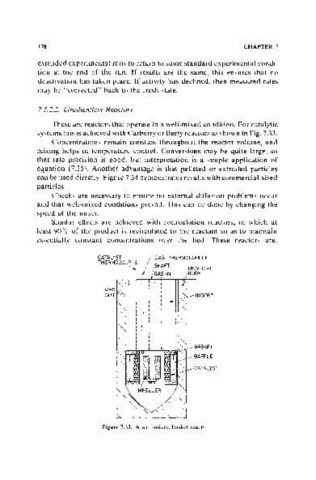

7.5.2.2. Gradientless Reactors

These are reactors that operate in a well-mixed condition. For catalytic

systems this is achieved with Carberry or Berty reactors as shown in Fig. 7.33.

Concentrations remain constant throughout the reactor volume, and

mixing helps in temperature control. Conversions may be quite large, so

that rate precision is good, but interpretation is a simple application of

equation (7.25). Another advantage is that pelleted or extruded particles

can be used directly. Figure 7.34 demonstrates results with commercial-sized

particles.

Checks are necessary to ensure no external diffusion problems occur

and that well-mixed conditions prevail. This can be done by changing the

speed of the mixer.

Similar effects are achieved with recirculation reactors, in which at

least 9()(~o of the product is recirculated to the reactant so as to maintain

essentially constant concentrations over the bed. These reactors are,

CATALYST GAS THERMOCOUPLE

THERMOCOUPLE (.

~""II SHAFT REACTOR

11 GA~ IN BODY

" I'

~INSERT

BASKET

BAFFLE

CATALYST

Figure 7.33. A well-mixed basket reactor.