Page 207 - Principles of Catalyst Development

P. 207

196 CHAPTER 8

CRYSTALLITE MIGRATION INTERPARTICLE TRANSFER

VAPOR

SURFACE

DIFFUSION

7797777777Q

( b)

(d)

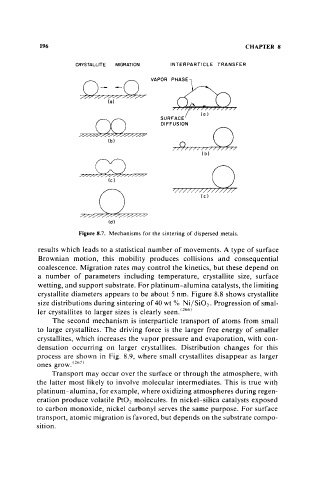

Figure 8.7. Mechanisms for the sintering of dispersed metals.

results which leads to a statistical number of movements. A type of surface

Brownian motion, this mobility produces collisions and consequential

coalescence. Migration rates may control the kinetics, but these depend on

a number of parameters including temperature, crystallite size, surface

wetting, and support substrate. For platinum-alumina catalysts, the limiting

crystallite diameters appears to be about 5 nm. Figure 8.8 shows crystallite

size distributions during sintering of 40 wt % Ni/Si0 2 • Progression of smal-

ler crystallites to larger sizes is clearly seen. (266)

The second mechanism is interparticle transport of atoms from small

to large crystallites. The driving force is the larger free energy of smaller

crystallites, which increases the vapor pressure and evaporation, with con-

densation occurring on larger crystallites. Distribution changes for this

process are shown in Fig. 8.9, where small crystallites disappear as larger

ones grow. (267)

Transport may occur over the surface or through the atmosphere, with

the latter most likely to involve molecular intermediates. This is true with

platinum-alumina, for example, where oxidizing atmospheres during regen-

eration produce volatile Pt0 2 molecules. In nickel-silica catalysts exposed

to carbon monoxide, nickel carbonyl serves the same purpose. For surface

transport, atomic migration is favored, but depends on the substrate compo-

sition.