Page 202 - Principles of Catalyst Development

P. 202

CATALYST DEACTIVATION 191

5. Addition of promoters to neutralize poisons. Sulfur poisoning of

nickel is reduced in the presence of copper chromite, since copper and

chromium ions preferentially form sulfides. Another example is heavy metals

poisoning of cracking catalyst, in which iron, nickel, and vanadium are

alloyed with antimony added to the feed and deposited on the catalyst.

The proper choice of which approach to follow, catalyst or process

modification, requires a detailed knowledge of the cause of the deactivation.

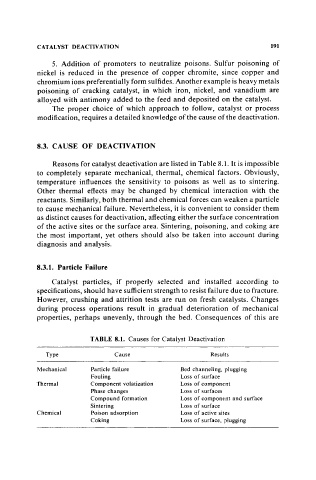

8.3. CAUSE OF DEACTIVATION

Reasons for catalyst deactivation are listed in Table 8.1. It is impossible

to completely separate mechanical, thermal, chemical factors. Obviously,

temperature influences the sensitivity to poisons as well as to sintering.

Other thermal effects may be changed by chemical intt::raction with the

reactants. Similarly, both thermal and chemical forces can weaken a particle

to cause mechanical failure. Nevertheless, it is convenient to consider them

as distinct causes for deactivation, affecting either the surface concentration

of the active sites or the surface area. Sintering, poisoning, and coking are

the most important, yet others should also be taken into account during

diagnosis and analysis.

8.3.1. Particle Failure

Catalyst particles, if properly selected and installed according to

specifications, should have sufficient strength to resist failure due to fracture.

However, crushing and attrition tests are run on fresh catalysts. Changes

during process operations result in gradual deterioration of mechanical

properties, perhaps unevenly, through the bed. Consequences of this are

TABLE 8.1. Causes for Catalyst Deactivation

Type Cause Results

Mechanical Particle failure Bed channeling, plugging

Fouling Loss of surface

Thermal Component volatization Loss of compont:nt

Phase changes Loss of surfaces

Compound formation Loss of component and surface

Sintering Loss of surface

Chemical Poison adsorption Loss of active sites

Coking Loss of surface, plugging