Page 33 - Principles of Catalyst Development

P. 33

CATALYTIC FUNCTIONS 19

1.5. DIAGNOSIS OF CATALYTIC FUNCTION

In order to understand and modify the functions of a catalyst in a

process, it is necessary to determine whether or not rates are determined

by physical or chemical steps. Responses to process parameters and catalyst

adjustments are different for the two regimes. Diffusional resistance, in

particular, causes unexpected complications. We have seen how low

effectiveness factors decrease conversion and disguise kinetics, but selec-

tivity also can be decreased.(32) In addition, poisoning of pore mouth sites

in conjunction with low diffusion results in a much more rapid activity

decline than otherwise.

Problems with diffusion-controlled processes are eased by changing

catalyst properties such as pore size distribution and particle size or process

conditions such as linear velocity. Chemical difficulties are treated through

modification of the active components of the catalyst.

The remainder of this chapter deals with determining the dominant

regime, physical or chemical, prevailing under a given set of conditions.

1.5.1. Interactions between Regimes

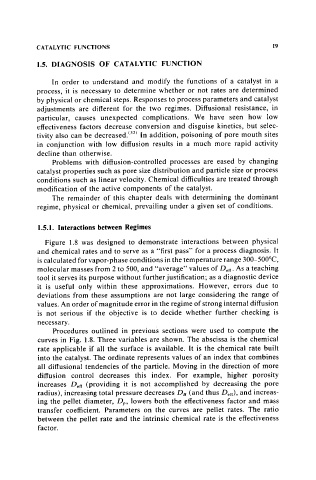

Figure 1.8 was designed to demonstrate interactions between physical

and chemical rates and to serve as a "first pass" for a process diagnosis. It

is calculated for vapor-phase conditions in the temperature range 300-500°C,

molecular masses from 2 to 500, and "average" values of D eff • As a teaching

tool it serves its purpose without further justification; as a diagnostic device

it is useful only within these approximations. However, errors due to

deviations from these assumptions are not large considering the range of

values. An order of magnitude error in the regime of strong internal diffusion

is not serious if the objective is to decide whether further checking is

necessary.

Procedures outlined in previous sections were used to compute the

curves in Fig. 1.8. Three variables are shown. The abscissa is the chemical

rate applicable if all the surface is available. It is the chemical rate built

into the catalyst. The ordinate represents values of an index that combines

all diffusional tendencies of the particle. Moving in the direction of more

diffusion control decreases this index. For example, higher porosity

increases Deff (providing it is not accomplished by decreasing the pore

radius), increasing total pressure decreases DB (and thus D eff ), and increas-

ing the pelIet diameter, D p , lowers both the effectiveness factor and mass

transfer coefficient. Parameters on the curves are pellet rates. The ratio

between the pellet rate and the intrinsic chemical rate is the effectiveness

factor.