Page 210 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 210

208 Chapter 7 Industrial cooling systems

FIBERGLASS FAN STACK

DRIVE SHAFT

GEAR

FAN

REDUCER PERIMETER

MOTOR HANDRAIL

DRIFT FAN DECK

ELIMINATORS

HOT WATER INLET

DISTRIBUTION

SYSTEM

PVC CORRUGATED

FILM

CASING PANEL

FILL

AIR INLET

COLD WATER BASIN

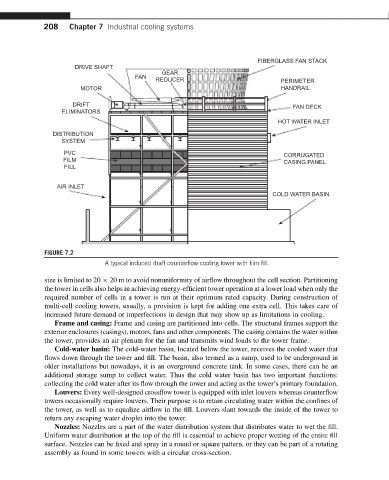

FIGURE 7.2

A typical induced draft counterflow cooling tower with film fill.

size is limited to 20 20 m to avoid nonuniformity of airflow throughout the cell section. Partitioning

the tower in cells also helps in achieving energy-efficient tower operation at a lower load when only the

required number of cells in a tower is run at their optimum rated capacity. During construction of

multi-cell cooling towers, usually, a provision is kept for adding one extra cell. This takes care of

increased future demand or imperfections in design that may show up as limitations in cooling.

Frame and casing: Frame and casing are partitioned into cells. The structural frames support the

exterior enclosures (casings), motors, fans and other components. The casing contains the water within

the tower, provides an air plenum for the fan and transmits wind loads to the tower frame.

Cold-water basin: The cold-water basin, located below the tower, receives the cooled water that

flows down through the tower and fill. The basin, also termed as a sump, used to be underground in

older installations but nowadays, it is an overground concrete tank. In some cases, there can be an

additional storage sump to collect water. Thus the cold water basin has two important functions:

collecting the cold water after its flow through the tower and acting as the tower’s primary foundation.

Louvers: Every well-designed crossflow tower is equipped with inlet louvers whereas counterflow

towers occasionally require louvers. Their purpose is to retain circulating water within the confines of

the tower, as well as to equalize airflow in the fill. Louvers slant towards the inside of the tower to

return any escaping water droplet into the tower.

Nozzles: Nozzles are a part of the water distribution system that distributes water to wet the fill.

Uniform water distribution at the top of the fill is essential to achieve proper wetting of the entire fill

surface. Nozzles can be fixed and spray in a round or square pattern, or they can be part of a rotating

assembly as found in some towers with a circular cross-section.