Page 215 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 215

7.2 Cooling tower 213

Cooling towers have certain design values, but the best cooling tower effectiveness requires

adjustment for seasonal variations and tuning of water and air flow rates. Adjustments can be made by

water box loading changes or blade angle adjustments.

7.2.4 Cooling water circuit in a process plant

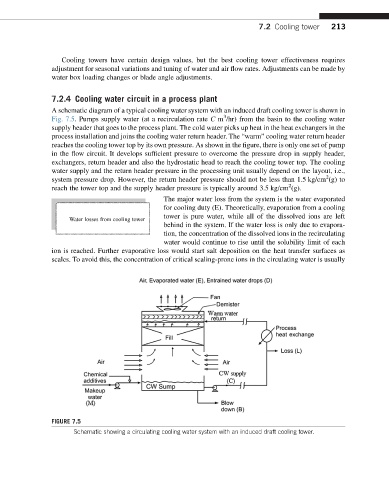

A schematic diagram of a typical cooling water system with an induced draft cooling tower is shown in

3

Fig. 7.5. Pumps supply water (at a recirculation rate C m /hr) from the basin to the cooling water

supply header that goes to the process plant. The cold water picks up heat in the heat exchangers in the

process installation and joins the cooling water return header. The “warm” cooling water return header

reaches the cooling tower top by its own pressure. As shown in the figure, there is only one set of pump

in the flow circuit. It develops sufficient pressure to overcome the pressure drop in supply header,

exchangers, return header and also the hydrostatic head to reach the cooling tower top. The cooling

water supply and the return header pressure in the processing unit usually depend on the layout, i.e.,

2

system pressure drop. However, the return header pressure should not be less than 1.5 kg/cm (g) to

2

reach the tower top and the supply header pressure is typically around 3.5 kg/cm (g).

The major water loss from the system is the water evaporated

for cooling duty (E). Theoretically, evaporation from a cooling

tower is pure water, while all of the dissolved ions are left

Water losses from cooling tower

behind in the system. If the water loss is only due to evapora-

tion, the concentration of the dissolved ions in the recirculating

water would continue to rise until the solubility limit of each

ion is reached. Further evaporative loss would start salt deposition on the heat transfer surfaces as

scales. To avoid this, the concentration of critical scaling-prone ions in the circulating water is usually

FIGURE 7.5

Schematic showing a circulating cooling water system with an induced draft cooling tower.