Page 34 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 34

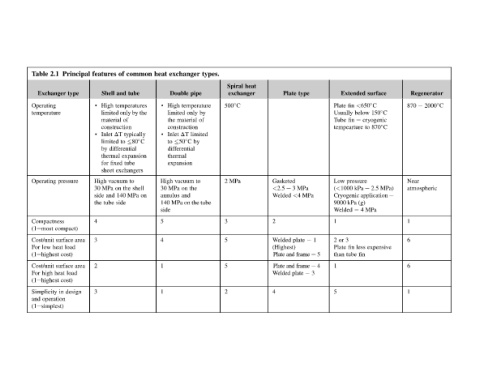

Regenerator 2000 C e 870 Near atmospheric 1 6 6 1

surface <650 C 150 C cryogenic 870 C to MPa) 2.5 e 4MPa expensive

Extended fin below e fin tempearture pressure kPa Cryogenic application e (g) kPa e less fin fin tube

Plate Usually Tube Low (<1000 9000 Welded 1 2or3 Plate than 1 5

1 3

type MPa <4MPa plate Plate and frame e 5 Plate and frame e 4 plate

Plate Gasketed 3 e <2.5 Welded 2 Welded (Highest) Welded 4

heat

Spiral exchanger 500 C MPa 2 3 5 5 2

types. by of limited to

exchanger pipe Double temperature High only limited material construction DT Inlet 50 Cby differential thermal expansion vacuum the on MPa and MPa on the tube

heat · the · to High 30 annulus 140 side 5 4 1 1

common tube temperatures typically 80 C expansion to shell on MPa

of and limited only by the of construction DT to differential tube fixed exchangers vacuum the on 140 side

features Shell High · material Inlet · limited by thermal for sheet High MPa 30 and side tube the 4 3 2 3

Principal type pressure compact) area load cost) area load cost) design

2.1 Exchanger Compactness surface heat surface heat in operation (1esimplest)

Table Operating temperature Operating (1emost Cost/unit low For (1ehighest Cost/unit high For (1ehighest Simplicity and