Page 29 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 29

2.2 Exchanger types 25

fluid when it flows through the matrix. Hence, the heat transfer is not unidirectional as in recuperators.

To operate with continuous flow of streams and limit the periodic temperature variation of the fluids,

either the matrix is physically moved periodically into and out of the fixed stream of gases (rotary

regenerator) or the gas flow is diverted using valves to and from the fixed matrices (fixed matrix

regenerator). A small amount of fluid is always trapped in the matrix that gets mixed with the other

fluid stream on switching of the fluids. Also a small leakage of the higher pressure fluid to the lower

pressure fluid is expected in real systems. Therefore, it cannot be used for systems where contami-

nation of one fluid by the other is unacceptable. In air heating applications, humid air may transfer

moisture up to about 5% to dry air. The advantages of regenerators over recuperators are

(a) compactness e smaller exchanger for given exchanger effectiveness and pressure drop, (b) cheaper

option, (c) simpler inlet and outlet header design for distribution of gases in the matrix and (d) can

work even with particulate laden gases that cause fouling in recuperators.

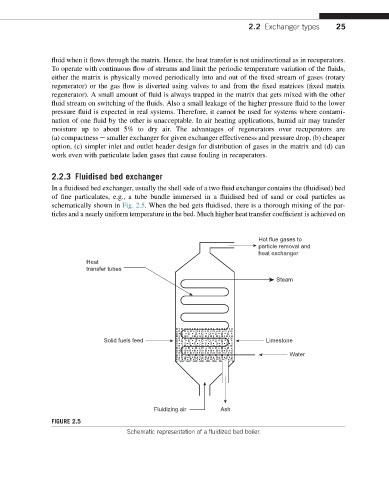

2.2.3 Fluidised bed exchanger

In a fluidised bed exchanger, usually the shell side of a two fluid exchanger contains the (fluidised) bed

of fine particulates, e.g., a tube bundle immersed in a fluidised bed of sand or coal particles as

schematically shown in Fig. 2.5. When the bed gets fluidised, there is a thorough mixing of the par-

ticles and a nearly uniform temperature in the bed. Much higher heat transfer coefficient is achieved on

Hot flue gases to

particle removal and

heat exchanger

Heat

transfer tubes

Steam

Solid fuels feed Limestone

Water

Fluidizing air Ash

FIGURE 2.5

Schematic representation of a fluidized bed boiler.