Page 48 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 48

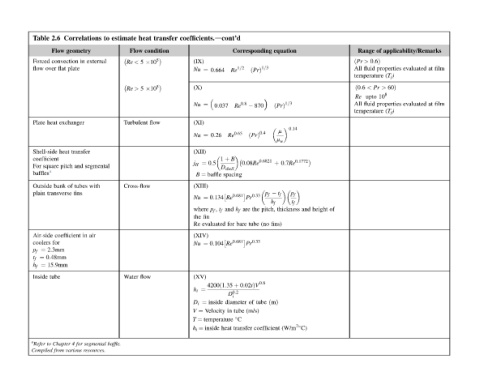

applicability/Remarks film at evaluated film at evaluated

of 0:6Þ properties (T f ) 60Þ > Pr 10 8 properties (T f )

Range ðPr > fluid All temperature < ð0:6 upto Re fluid All temperature

of

height and

equation ðPrÞ 1=3 0:14 m m w 0:7Re 0:1772 þ t f p f t f h f thickness fins) ðmÞ (W/m 2 C)

Corresponding ðPrÞ 1=3 Re 1=2 870Þ Re 0:8 ðPrÞ 0:4 Re 0:65 1 þ B 0:08Re 0:6821 spacing p f 0:134 Re 0:681 Pr 0:33 pitch, the are h f (no tube bare 0:104 Re 0:681 Pr 0:33 4200ð1:35 þ 0:02tÞV 0:8 D 0:2 i tube of diameter (m/s) tube C coefficient transfer

coefficients.dcont’d (IX) ¼ Nu 0:664 (X) ¼ Nu 0:037 (XI) 0:26 ¼ Nu (XII) 0:5 ¼ j H D shell baffle ¼ B (XIII) ¼ Nu and t f p f , where fin the for evaluated Re (XIV) ¼ Nu (XV) ¼ h i inside ¼ D i in Velocity ¼ V temperature ¼ T heat inside ¼ h i

transfer condition

heat Flow 10 5 5 10 5 5 flow Turbulent Cross-flow flow

estimate Re < Re > Water

to external segmental baffle. segmental

Correlations geometry in plate exchanger transfer and with tubes of fins air in for 4 resources. various

2.6 Flow convection flat over heat heat pitch square bank transverse coefficient for 2:3mm 0:48mm 15:9mm tube Chapter to from

Table Forced flow Plate Shell-side coefficient For baffles a Outside plain Air-side coolers ¼ p f ¼ t f ¼ h f Inside a Refer Compiled