Page 137 - Process simulation and control using Aspen

P. 137

126 PROCESS SIMULATION AND CONTROL USING ASPEN 1"

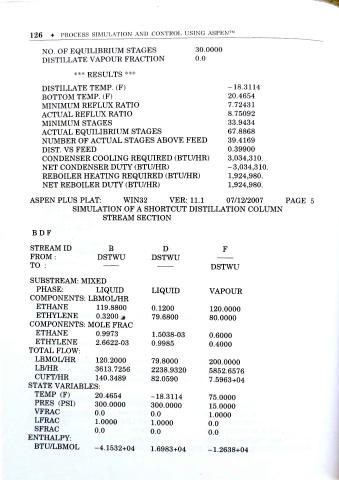

NO. OF EQUILIBRIUM STAGES 30.0000

DISTILLATE VAPOUR FRACTION 0 . 0

*** RESULTS ***

DISTILLATE TEMP. (F) -18.3114

BOTTOM TEMP. (F) 20.4654

MINIMUM REFLUX RATIO 7.72431

ACTUAL REFLUX RATIO 8.75092

MINIMUM STAGES 33.9434

ACTUAL EQUILIBRIUM STAGES 67.8868

NUMBER OF ACTUAL STAGES ABOVE FEED 39.4169

DIST. VS FEED 0.39900

CONDENSER COOLING REQUIRED (BTU/HR) 3,034,310.

NET CONDENSER DUTY (BTU/HR) -3,034,310.

REBOILER HEATING REQUIRED (BTU/HR) 1,924,980.

NET REBOILER DUTY (BTU/HR) 1,924,980.

ASPEN PLUS PLAT: WIN32 VER: 11.1 07/12/2007 PAGE

SIMULATION OF A SHORTCUT DISTILLATION COLUMN

STREAM SECTION

BDF

STREAM ID B D F

FROM: DSTWU DSTWU

TO : DSTWU

SUBSTREAM: MIXED

PHASE: LIQUID LIQUID VAPOUR

COMPONENTS: LBMOL/HR

ETHANE 119.8800 0 .1200 120.0000

ETHYLENE 0 .3200 79.6800 80.0000

COMPONENTS: MOLE FRAC

ETHANE 0 .9973 1 .5038-03 0 .6000

ETHYLENE 2 .6622-03 0 9985

. 0 .4000

TOTAL FLOW:

LBMOL/HR 120.2000 79.8000 200.0000

LB/HR 3613.7256 2238.9320 5852.6576

CUFT/HR 140.3489 82.0590 7 .5963+04

STATE VARIABLES:

TEMP (F) 20.4654 - 18.3114 75.0000

PRES (PSI) 300.0000 300.0000 15.0000

VFRAC 0 . 0 0 . 0 1 .0000

LFRAC 1 .0000 1 .0000 0 .0

SFRAC 0 . 0 0 . 0 0 . 0

ENTHALPY:

BTU/LBMOL - 4 .1532+04 1 .6983+04 -1 .2638+04