Page 71 - Process simulation and control using Aspen

P. 71

64 PROCESS SIMULATION AND CONTROL USING ASPEN

Fc f Edt Vfew 0«a Into ftjn nowheri Lfc fy VAk w Het

' lup I , IT _ LiiE| | |a|

-

EES;: gIBl«l|Oi. £lal«l|'rj. .aaJj'lL

Mto SlAtM | Salami | HealEKclwgeij | Cokfwx naactan | pienueChange!i | Manpiaton | 5cM« [ UmModeb |

S 0 U 31U

,

STREAMS 1 BSinc BEoii HGMis RCSTB BPItg RBaM.

\ s FoWen JJswn Ru» H 1 HUM lfloAi Atfahie

r

FIGURE 2.15

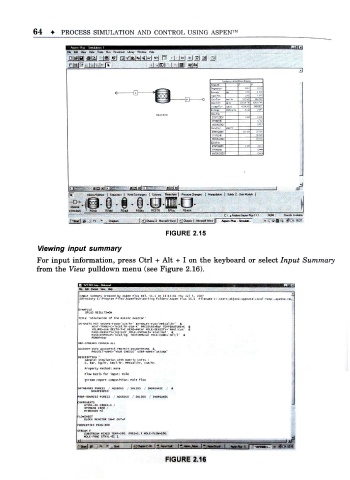

Viewing input summary

For input information, press Ctrl + Alt + I on the keyboard or select Input Summary

from the View pulldown menu (see Figure 2.16).

CBSES

Fie £* Forw* >Atw

input Sugary created by Aspen Plus K«1. 11.1 at 12:U:CM Thu jul 5, 300?

Oirecrory C: Proqr-5R Pi les'AspenTech .norfcing Pol ders'.Aspen Plus 11.1 Fllep e Ci Users-.akjana.AppMtaMocal Terep -ape906.tK}

'

.

title 'SlmUllon of the fiStolc Reactor"

IN-UNITS KET VOLU> E-FLOS<- cuB hr ENTM*LPV-Fl.O-'*»lkcal/hr' A

"

'

HCAT-TRAHS-C- kcal/hr-sqn-K" PRESSURE"bar TEMPERATURE-C &

'

VOLUHE-CUIT OELTA-T-C HEAD-neter httLE-DENSin'- fcisol/cuni' &

'

fASS-DENSITV- kg.'CUH" W)LE-£NTHALP- kcal,'noV t,

'

'

t-ASS-EWTM .P- kcal/kg' HE*T-MMkcal t'OLE-CONC-'mol . T &

POBOP-bar

OCF-STREAt'S COMVEN AIL

DESCRIPTIOH "

General SlHllailoi) mith Metric units :

C, bar, kg/hr, knclhr. MMKcal/hr, c\m/hr.

property Method: Mone

Flow basis for Input: Kole

Stream report cooposltlon: Kole flow

ROP-SOURCES PUBEll - AQUEOUS / SOLIDS f INORGANIC

COMPONENTS

ETHYL-01 C8H10-4 /

STVRENE C8H8 ,'

HVOiOGEN H2

f

PBOPERTIFS PENG-ROB

5THCAH F

SUBSTBEAf KIXEO TCHP-J60. PRE5-1.S MOLE-FLOW-100.

W>LE-FMC ETHYL-01 1.

t

t

B i I vjnwi-* |- la»«Jol | lo.»,-s || -WEME1 :« jpCitU

t

'

FIGURE 2.16