Page 72 - Process simulation and control using Aspen

P. 72

- y wkjusu, jO t 65

f

DO

If one may wish to generate a report file (* rep) for the nrp f u,

instructions as presented in Chapter 1 P eSent Problem, follow the

.

2 .

3 ASPEN PLUS SIMULATION OF A RCSTR MODE L

Problem statement

The hydrogenation of aniline produces cyclohexylamine i

'

following reaction: n a CSTR accord f

accor(lirig to the

C6H5NH2 + 3H 2 CeHnNHa

aniline hydrogen cyclohexylamine

The reactor operates at 40 bar and 120oC , and its volume is 1200 ft3 (75% li quid) For

the liquid-phase reaction, the inlet streams have the specifications shown in Table 2 1

,

. .

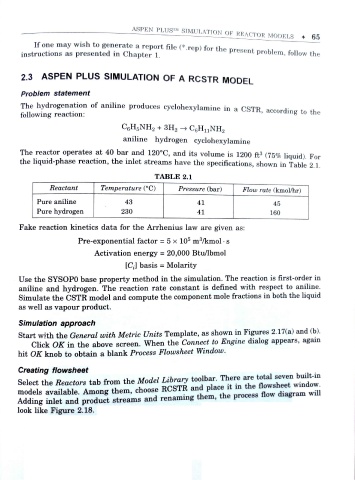

TABLE 2.1

Reactant Temperature (0C) Pressure (bar) Flow rate (kmol/hr)

Pure aniline 43 41 45

Pure hydrogen 230 41 160

Fake reaction kinetics data for the Arrhenius law are given as:

Pre-exponential factor = 5 x 105 m3/kmol s

Activation energy = 20,000 Btu/lbmol

[CJ basis = Molarity

Use the SYSOP0 base property method in the simulation. The reaction is first-order in

aniline and hydrogen. The reaction rate constant is defined with respect to an iline.

Simulate the CSTR model and compute the component mole fractions in both the liquid

as well as vapour product.

Simulation approach

Start with the General with Metric Units Template, as shown in Figures 2.1 7(a) and (b).

Click OK in the above screen. When the Connect to Engine dialog appears, again

hit OK knob to obtain a blank Process Flowsheet Window.

Creating flowsheet

Select theReactors tab from the ModelLitwy t

models available. Among them, choose RCSTR P ce it in tn

Adding inlet and product streams and renaming them, the process flow magr

look like Figure 2.18.