Page 175 - Radiochemistry and nuclear chemistry

P. 175

Absorption of Nuclear Radiation 159

|

@

|

|

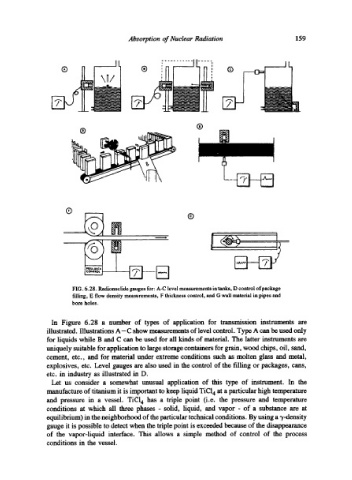

FIG. 6.28. Radionuclide gauges for: A-C level measurements in tanks, D control of package

filling, E flow density measurements, F thickness control, and G wall material in pipes and

bore holes.

In Figure 6.28 a number of types of application for transmission instruments are

illustrated. Illustrations A-C show measurements of level control. Type A can be used only

for liquids while B and C can be used for all kinds of material. The latter instruments are

uniquely suitable for application to large storage containers for grain, wood chips, oil, sand,

cement, etc., and for material under extreme conditions such as molten glass and metal,

explosives, etc. Level gauges are also used in the control of the filling or packages, cans,

etc. in industry as illustrated in D.

Let us consider a somewhat unusual application of this type of instrument. In the

manufacture of titanium it is important to keep liquid TiCl 4 at a particular high temperature

and pressure in a vessel. TiC14 has a triple point (i.e. the pressure and temperature

conditions at which all three phases - solid, liquid, and vapor - of a substance are at

equilibrium) in the neighborhood of the particular technical conditions. By using a "y-density

gauge it is possible to detect when the triple point is exceeded because of the disappearance

of the vapor-liquid interface. This allows a simple method of control of the process

conditions in the vessel.