Page 33 - Rapid Learning in Robotics

P. 33

2.3 Sensing: Tactile Perception 19

2.3 Sensing: Tactile Perception

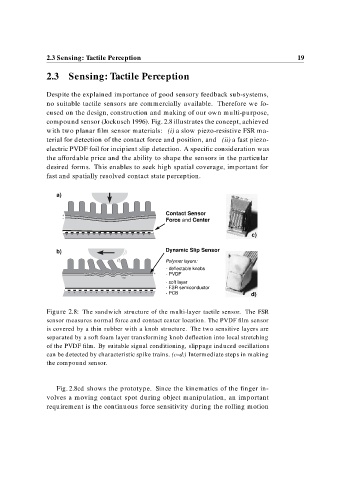

Despite the explained importance of good sensory feedback sub-systems,

no suitable tactile sensors are commercially available. Therefore we fo-

cused on the design, construction and making of our own multi-purpose,

compound sensor (Jockusch 1996). Fig. 2.8 illustrates the concept, achieved

with two planar film sensor materials: (i) a slow piezo-resistive FSR ma-

terial for detection of the contact force and position, and (ii) a fast piezo-

electric PVDF foil for incipient slip detection. A specific consideration was

the affordable price and the ability to shape the sensors in the particular

desired forms. This enables to seek high spatial coverage, important for

fast and spatially resolved contact state perception.

a)

Contact Sensor

Force and Center

c)

b) Dynamic Slip Sensor

Polymer layers:

- deflectable knobs

- PVDF

- soft layer

- FSR semiconductor

- PCB d)

Figure 2.8: The sandwich structure of the multi-layer tactile sensor. The FSR

sensor measures normal force and contact center location. The PVDF film sensor

is covered by a thin rubber with a knob structure. The two sensitive layers are

separated by a soft foam layer transforming knob deflection into local stretching

of the PVDF film. By suitable signal conditioning, slippage induced oscillations

can be detected by characteristic spike trains. (c–d:) Intermediate steps in making

the compound sensor.

Fig. 2.8cd shows the prototype. Since the kinematics of the finger in-

volves a moving contact spot during object manipulation, an important

requirement is the continuous force sensitivity during the rolling motion