Page 31 - Rapid Learning in Robotics

P. 31

2.2 Actuation: The Hand “Manus” 17

2.2.1 Oil model

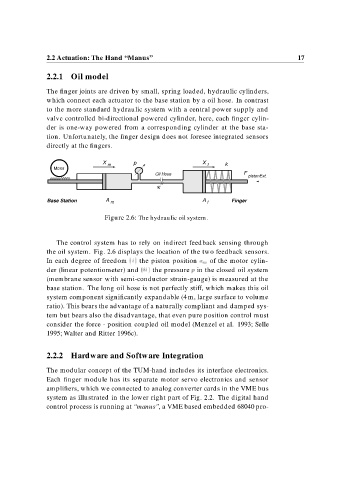

The finger joints are driven by small, spring loaded, hydraulic cylinders,

which connect each actuator to the base station by a oil hose. In contrast

to the more standard hydraulic system with a central power supply and

valve controlled bi-directional powered cylinder, here, each finger cylin-

der is one-way powered from a corresponding cylinder at the base sta-

tion. Unfortunately, the finger design does not foresee integrated sensors

directly at the fingers.

X p X

m f k

Motor

Oil Hose F

pistonExt.

κ

Base Station A m A f Finger

Figure 2.6: The hydraulic oil system.

The control system has to rely on indirect feedback sensing through

the oil system. Fig. 2.6 displays the location of the two feedback sensors.

In each degree of freedom i the piston position x m of the motor cylin-

der (linear potentiometer) and ii the pressure p in the closed oil system

(membrane sensor with semi-conductor strain-gauge) is measured at the

base station. The long oil hose is not perfectly stiff, which makes this oil

system component significantly expandable (4 m, large surface to volume

ratio). This bears the advantage of a naturally compliant and damped sys-

tem but bears also the disadvantage, that even pure position control must

consider the force - position coupled oil model (Menzel et al. 1993; Selle

1995; Walter and Ritter 1996c).

2.2.2 Hardware and Software Integration

The modular concept of the TUM-hand includes its interface electronics.

Each finger module has its separate motor servo electronics and sensor

amplifiers, which we connected to analog converter cards in the VME bus

system as illustrated in the lower right part of Fig. 2.2. The digital hand

control process is running at “manus”, a VME based embedded 68040 pro-