Page 112 - Reciprocating Compressors Operation Maintenance

P. 112

Design and Mate rials for Reciprocating Compressor Components 09

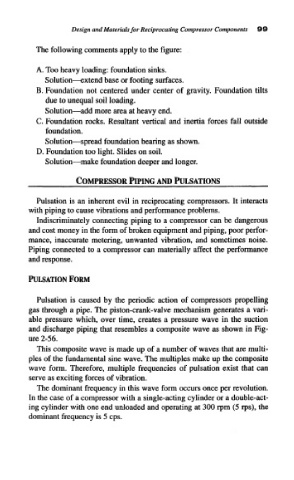

The following comments apply to the figure:

A. Too heavy loading: foundation sinks.

Solution—extend base or footing surfaces.

B. Foundation not centered under center of gravity. Foundation tilts

due to unequal soil loading.

Solution—add more area at heavy end.

C. Foundation rocks. Resultant vertical and inertia forces fall outside

foundation.

Solution—spread foundation bearing as shown.

D. Foundation too light. Slides on soil.

Solution—make foundation deeper and longer.

Pulsation is an inherent evil in reciprocating compressors. It interacts

with piping to cause vibrations and performance problems.

Indiscriminately connecting piping to a compressor can be dangerous

and cost money in the form of broken equipment and piping, poor perfor-

mance, inaccurate metering, unwanted vibration, and sometimes noise.

Piping connected to a compressor can materially affect the performance

and response.

PULSATION FORM

Pulsation is caused by the periodic action of compressors propelling

gas through a pipe. The piston-crank-valve mechanism generates a vari-

able pressure which, over time, creates a pressure wave in the suction

and discharge piping that resembles a composite wave as shown in Fig-

ure 2-56.

This composite wave is made up of a number of waves that are multi-

ples of the fundamental sine wave. The multiples make up the composite

wave form. Therefore, multiple frequencies of pulsation exist that can

serve as exciting forces of vibration.

The dominant frequency in this wave form occurs once per revolution.

In the case of a compressor with a single-acting cylinder or a double-act-

ing cylinder with one end unloaded and operating at 300 rpm (5 rps), the

dominant frequency is 5 cps.