Page 113 - Reciprocating Compressors Operation Maintenance

P. 113

1OO Reciprocating Compressors: Operation and Maintenance

Crank ntren

/A

"N \

/ j Canjwitt*

\

s ^

1 /

1

i \ 1 i tpunoomnna

tEkMulMN»AM*M

,

, .., X«4y

/ \ / i

y Vj

•>

-^ ^ H ^h 3

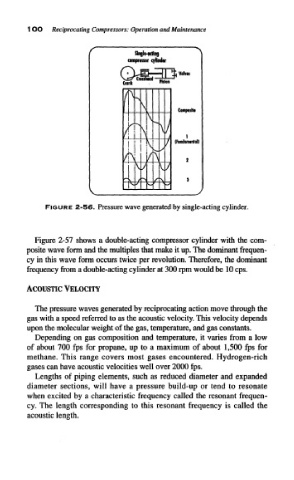

FIGURE 2-56. Pressure wave generated by single-acting cylinder.

Figure 2-57 shows a double-acting compressor cylinder with the com-

posite wave form and the multiples that make it up. The dominant frequen-

cy in this wave form occurs twice per revolution. Therefore, the dominant

frequency from a double-acting cylinder at 300 rpm would be 10 cps.

The pressure waves generated by reciprocating action move through the

gas with a speed referred to as the acoustic velocity. This velocity depends

upon the molecular weight of the gas, temperature, and gas constants.

Depending on gas composition and temperature, it varies from a low

of about 700 fps for propane, up to a maximum of about 1,500 fps for

methane. This range covers most gases encountered. Hydrogen-rich

gases can have acoustic velocities well over 2000 fps.

Lengths of piping elements, such as reduced diameter and expanded

diameter sections, will have a pressure build-up or tend to resonate

when excited by a characteristic frequency called the resonant frequen-

cy. The length corresponding to this resonant frequency is called the

acoustic length.