Page 158 - Reciprocating Compressors Operation Maintenance

P. 158

144 Reciprocating Compressors: Operation and Maintenance

is considered a high-speed valve although it can be applied equally well

to low-speed machines.

Plate valves, concentric ring and ported types, are not the most effi-

cient nor the least expensive valves, but they are more widely used than

other types for one reason: flexibility. They can use metal or plastic

plates, can use mass damping, and can be made with many narrow plates

or a few wide ones, and thus can be effective over a wide range of lifts.

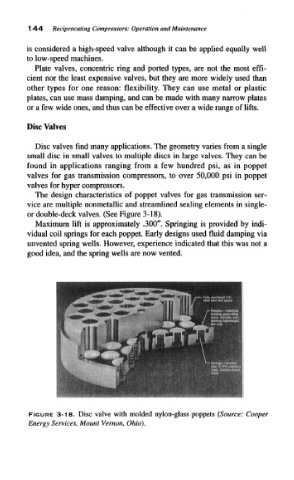

Disc Valves

Disc valves find many applications. The geometry varies from a single

small disc in small valves to multiple discs in large valves. They can be

found in applications ranging from a few hundred psi, as in poppet

valves for gas transmission compressors, to over 50,000 psi in poppet

valves for hyper compressors.

The design characteristics of poppet valves for gas transmission ser-

vice are multiple nonmetallic and streamlined sealing elements in single-

or double-deck valves. (See Figure 3-18).

Maximum lift is approximately .300". Springing is provided by indi-

vidual coil springs for each poppet. Early designs used fluid damping via

unvented spring wells. However, experience indicated that this was not a

good idea, and the spring wells are now vented.

FIGURE 3-18. Disc valve with molded nylon-glass poppets (Source: Cooper

Energy Services, Mount Vernon, Ohio).