Page 161 - Reciprocating Compressors Operation Maintenance

P. 161

Operation and Maintenance of Reciprocating Compressors t 47

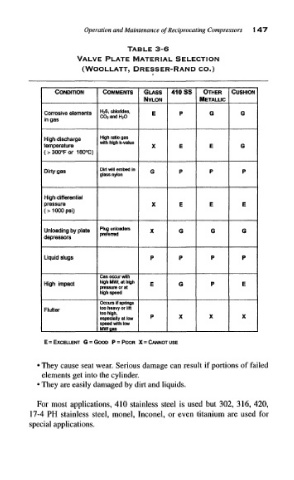

TABLE 3-6

VALVE PLATE MATERIAL SELECTION

(WOOLLATT, DRESSER-RAND co.)

CONDITION COMMENTS GLASS 410 S3 OTHER CUSHION

NYLON METALLIC

Corrosive elements H 2S, chlorides. E P G G

in gas COj and H 2O

High ratio gas

High discharge with high k-value

temperature X E E G

(>300°For 180°C)

Dirty gas Dirt will embed In 6 P P p

glass nylon

High differentia!

pressure X E E E

{ > 1000 psi)

Unloading by plate Plug unloaders X G G G

preferred

depressors

Liquid slugs P P P P

Can occur with

High impact high MW, at high E G P E

pressure or at

high speed

Occurs if springs

Flutter too heavy or lift

too high,

especially at low P X X X

speed with low

MWaas

E= EXCELLENT G = Gooo P = POOR X = CANNOT USE

* They cause seat wear. Serious damage can result if portions of failed

elements get into the cylinder.

* They are easily damaged by dirt and liquids.

For most applications, 410 stainless steel is used but 302, 316, 420,

17-4 PH stainless steel, monel, Inconel, or even titanium are used for

special applications.