Page 153 - Reciprocating Compressors Operation Maintenance

P. 153

Operation and Maintenance of Reciprocating Compressors 1 3S

Rectangular Element Valves

Typical valve designs that use rectangular elements are feather valves,

channel valves and reed valves. These valves generally make excellent

use of available valve port areas to provide flow area at moderate valve

lifts (.100"-.2(XD.

The rectangular shape of the elements eliminates the use of a cross-

ribbing system to provide structural integrity of the valve seat and guard.

This enables the use of long uninterrupted slots in the seat and guard and

provides good flow area.

Feather Valves

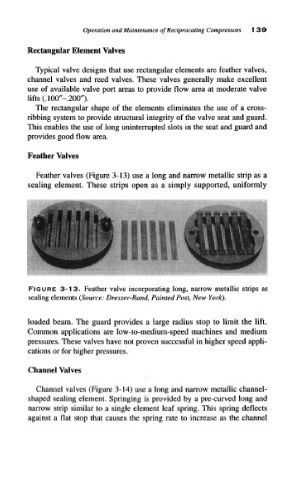

Feather valves (Figure 3-13) use a long and narrow metallic strip as a

sealing element. These strips open as a simply supported, uniformly

FIGURE 3-13. Feather valve incorporating long, narrow metallic strips as

sealing elements (Source: Dresser-Rand, Painted Post, New York).

loaded beam. The guard provides a large radius stop to limit the lift.

Common applications are low-to-medium-speed machines and medium

pressures. These valves have not proven successful in higher speed appli-

cations or for higher pressures.

Channel Valves

Channel valves (Figure 3-14) use a long and narrow metallic channel-

shaped sealing element. Springing is provided by a pre-curved long and

naiTow strip similar to a single element leaf spring. This spring deflects

against a flat stop that causes the spring rate to increase as the channel