Page 152 - Reciprocating Compressors Operation Maintenance

P. 152

1 38 Reciprocating Compressors: Operation and Maintenance

The difference between suction and discharge events

The basic cycle repeats itself over and over again and is representative

for every valve of every design and configuration.

The differences between suction and discharge events are the piston

velocities at which the suction versus the discharge valves open and

close, the time the total cycle consumes, and the pressure and tempera-

ture at which the gas is being processed.

These criteria are important to remember because they lead to the

design differences between suction and discharge valves.

VALVE TYPES USED IN RECIPROCATING COMPRESSORS

Prior to the development of automatic valves, compressors used

mechanically operated suction and heavy poppet-type discharge valves.

These valve types were efficient and satisfactory at relatively low rota-

tive speeds, but limited the speeds at which the compressors could oper-

ate. The lightweight, fully automatic valve allowed for higher rotative

speeds, greater output, and increased efficiency from the compressor.

There are many different valve designs available for modern recipro-

cating compressors. They all function as check valves, opening and clos-

ing as a function of differential pressures as well as keeping the fluid in

the compressor cylinder during the compression process.

However, these designs can be classified into relatively few types,

defined by the shape of moving elements and the nature of damping used

to control the motion. Table 3-4 summarizes these valve types and the

following paragraphs give a brief description of each type.

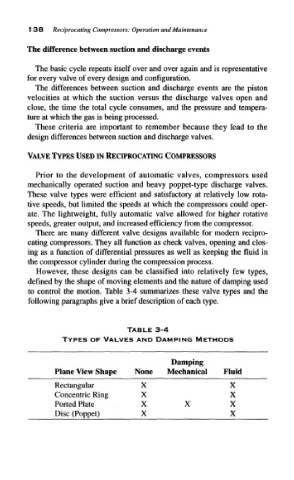

TABLE 3-4

TYPES OF VALVES AND DAMPING METHODS

Damping

Plane View Shape None Mechanical Fluid

Rectangular X X

Concentric Ring X X

Ported Plate X X X

Disc (Poppet) X X