Page 175 - Reciprocating Compressors Operation Maintenance

P. 175

Operation and Maintenance of Reciprocating Compressors 161

PE;M VALVE RESTRAIN n

GASKET-x ftl—JACKBOLT

•NUT

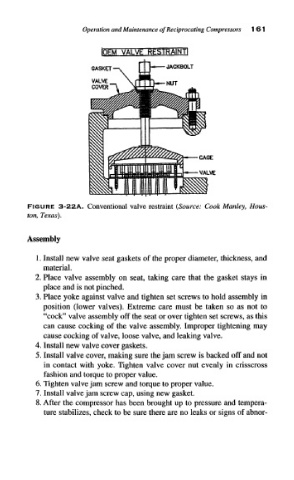

FIGURE 3-22A. Conventional valve restraint (Source: Cook Manley, Hous-

ton, Texas).

Assembly

1. Install new valve seat gaskets of the proper diameter, thickness, and

material.

2. Place valve assembly on seat, taking care that the gasket stays in

place and is not pinched.

3. Place yoke against valve and tighten set screws to hold assembly in

position (lower valves). Extreme care must be taken so as not to

"cock" valve assembly off the seat or over tighten set screws, as this

can cause cocking of the valve assembly. Improper tightening may

cause cocking of valve, loose valve, and leaking valve.

4. Install new valve cover gaskets.

5. Install valve cover, making sure the jam screw is backed off and not

in contact with yoke. Tighten valve cover nut evenly in crisscross

fashion and torque to proper value.

6. Tighten valve jam screw and torque to proper value.

7. Install valve jam screw cap, using new gasket.

8. After the compressor has been brought up to pressure and tempera-

ture stabilizes, check to be sure there are no leaks or signs of abnor-