Page 180 - Reciprocating Compressors Operation Maintenance

P. 180

1 66 Reciprocating Compressors: Operation and Maintenance

Testing

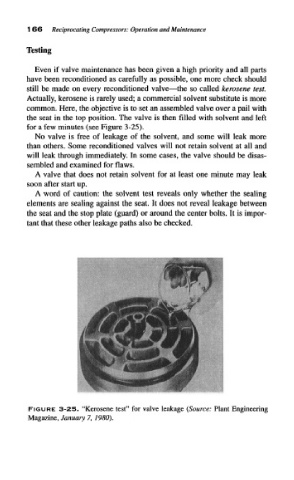

Even if valve maintenance has been given a high priority and all parts

have been reconditioned as carefully as possible, one more check should

still be made on every reconditioned valve—the so called kerosene test,

Actually, kerosene is rarely used; a commercial solvent substitute is more

common. Here, the objective is to set an assembled valve over a pail with

the seat in the top position. The valve is then filled with solvent and left

for a few minutes (see Figure 3-25).

No valve is free of leakage of the solvent, and some will leak more

than others. Some reconditioned valves will not retain solvent at all and

will leak through immediately. In some cases, the valve should be disas-

sembled and examined for flaws.

A valve that does not retain solvent for at least one minute may leak

soon after start up.

A word of caution: the solvent test reveals only whether the sealing

elements are sealing against the seat. It does not reveal leakage between

the seat and the stop plate (guard) or around the center bolts. It is impor-

tant that these other leakage paths also be checked.

FIGURE 3-25, "Kerosene test" for valve leakage (Source: Plant Engineering

Magazine, January 7, 1980).