Page 181 - Reciprocating Compressors Operation Maintenance

P. 181

Operation and Maintenance of Reciprocating Compressors 1 67

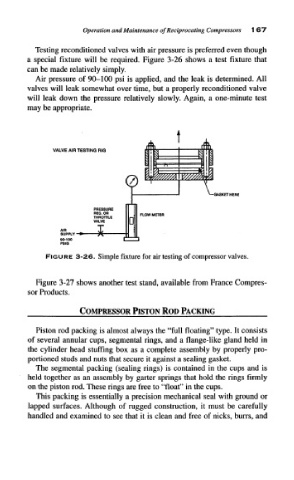

Testing reconditioned valves with air pressure is preferred even though

a special fixture will be required. Figure 3-26 shows a test fixture that

can be made relatively simply.

Air pressure of 90-100 psi is applied, and the leak is determined. All

valves will leak somewhat over time, but a properly reconditioned valve

will leak down the pressure relatively slowly. Again, a one-minute test

may be appropriate.

VALVE AIR TESTING B»Q

PRESSURE

HEG.OR FLOW METER

THROTTLE

VALVE D

AIR -X —

SUPPLY

ao-ioo -*—

PSIQ

FIGURE 3-26. Simple fixture for air testing of compressor valves.

Figure 3-27 shows another test stand, available from France Compres-

sor Products.

COMPRESSOR PISTON ROD PACKING

Piston rod packing is almost always the "full floating" type. It consists

of several annular cups, segmental rings, and a flange-like gland held in

the cylinder head stuffing box as a complete assembly by properly pro-

portioned studs and nuts that secure it against a sealing gasket.

The segmental packing (sealing rings) is contained in the cups and is

held together as an assembly by garter springs that hold the rings firmly

on the piston rod. These rings are free to "float" in the cups.

This packing is essentially a precision mechanical seal with ground or

lapped surfaces. Although of rugged construction, it must be carefully

handled and examined to see that it is clean and free of nicks, burrs, and