Page 177 - Reciprocating Compressors Operation Maintenance

P. 177

Operation and Maintenance of Reciprocating Compressors 1 63

ICQQK MANLEYHSRI

MULT1PIE BOLTS VALVE

it SP. WASHERS TNrtn trhn PCOVER

0-RIN6S

U-VALVE

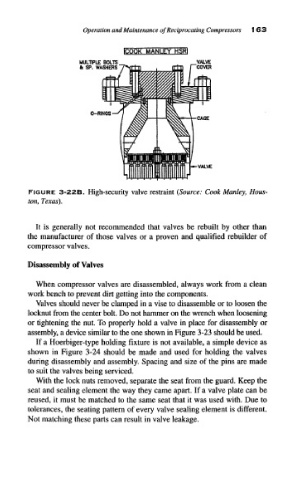

FIGURE 3-22B. High-security valve restraint (Source: Cook Manley, Hous-

ton, Texas).

It is generally not recommended that valves be rebuilt by other than

the manufacturer of those valves or a proven and qualified rebuilder of

compressor valves.

Disassembly of Valves

When compressor valves are disassembled, always work from a clean

work bench to prevent dirt getting into the components.

Valves should never be clamped in a vise to disassemble or to loosen the

locknut from the center bolt. Do not hammer on the wrench when loosening

or tightening the nut. To properly hold a valve in place for disassembly or

assembly, a device similar to the one shown in Figure 3-23 should be used.

If a Hoerbiger-type holding fixture is not available, a simple device as

shown in Figure 3-24 should be made and used for holding the valves

during disassembly and assembly. Spacing and size of the pins are made

to suit the valves being serviced.

With the lock nuts removed, separate the seat from the guard. Keep the

seat and sealing element the way they came apart. If a valve plate can be

reused, it must be matched to the same seat that it was used with. Due to

tolerances, the seating pattern of every valve sealing element is different.

Not matching these parts can result in valve leakage.