Page 194 - Reciprocating Compressors Operation Maintenance

P. 194

I 80 Reciprocating Compressors: Operation and Maintenance

The metal back-up ring prevents extrusion and aids in removing

friction heat from the rod surface. The ring is bored a few thou-

sandths larger than the rod diameter, with zero clearance at the

joints to assure a tight gas seal.

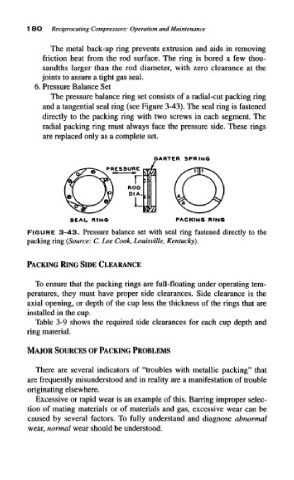

6. Pressure Balance Set

The pressure balance ring set consists of a radial-cut packing ring

and a tangential seal ring (see Figure 3-43). The seal ring is fastened

directly to the packing ring with two screws in each segment. The

radial packing ring must always face the pressure side. These rings

are replaced only as a complete set.

GARTER SPRING

SEAL RING PACKING RING

FIGURE 3-43. Pressure balance set with seal ring fastened directly to the

packing ring (Source: C. Lee Cook, Louisville, Kentucky).

PACKING RING SIDE CLEARANCE

To ensure that the packing rings are full-floating under operating tem-

peratures, they must have proper side clearances. Side clearance is the

axial opening, or depth of the cup less the thickness of the rings that are

installed in the cup.

Table 3-9 shows the required side clearances for each cup depth and

ring material.

MAJOR SOURCES OF PACKING PROBLEMS

There are several indicators of "troubles with metallic packing" that

are frequently misunderstood and in reality are a manifestation of trouble

originating elsewhere.

Excessive or rapid wear is an example of this. Barring improper selec-

tion of mating materials or of materials and gas, excessive wear can be

caused by several factors. To fully understand and diagnose abnormal

wear, normal wear should be understood.