Page 195 - Reciprocating Compressors Operation Maintenance

P. 195

Operation and Maintenance of Reciprocating Compressors 181

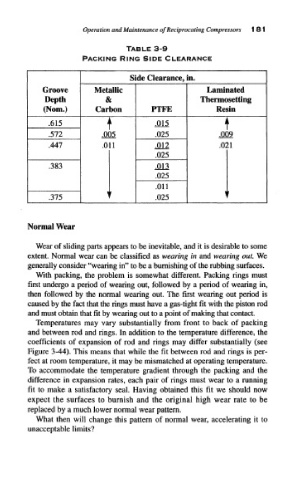

TABLE 3-9

PACKING RING SIDE CLEARANCE

Side Clearance, in.

Groove Metallic Laminated

Depth & Thermosetting

(Norn.) Carbon PTFE Resin

.615 t M5 t

.572 .005 .025 .009

.447 .011 .012 .021

.025

383 .013

.025

.011

1 i 1 r

375 .025

Normal Wear

Wear of sliding parts appears to be inevitable, and it is desirable to some

extent. Normal wear can be classified as wearing in and wearing out. We

generally consider "wearing in" to be a burnishing of the rubbing surfaces.

With packing, the problem is somewhat different. Packing rings must

first undergo a period of wearing out, followed by a period of wearing in,

then followed by the normal wearing out. The first wearing out period is

caused by the fact that the rings must have a gas-tight fit with the piston rod

and must obtain that fit by wearing out to a point of making that contact.

Temperatures may vary substantially from front to back of packing

and between rod and rings. In addition to the temperature difference, the

coefficients of expansion of rod and rings may differ substantially (see

Figure 3-44). This means that while the fit between rod and rings is per-

fect at room temperature, it may be mismatched at operating temperature.

To accommodate the temperature gradient through the packing and the

difference in expansion rates, each pair of rings must wear to a running

fit to make a satisfactory seal. Having obtained this fit we should now

expect the surfaces to burnish and the original high wear rate to be

replaced by a much lower normal wear pattern.

What then will change this pattern of normal wear, accelerating it to

unacceptable limits?