Page 192 - Reciprocating Compressors Operation Maintenance

P. 192

178 Reciprocating Compressors: Operation and Maintenance

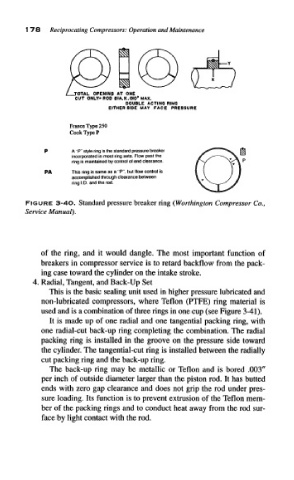

.TOTAL OPENING AT ONE

CUT ONLY" ROD 01 A. X .010" MAX.

DOUBLE ACTING RING

EITHER SIDE MAY FACE PRESSURE

France Type 250

Cook Type P

P A P' style ring is the standard pressure breaker

incorporated in most ring sets. Flow past the

ring is maintained by control of end clearance.

PA This ring is same as a "P". but flow control is

accomplished through clearance between

ring I.D. and the rod.

FIGURE 3-4O. Standard pressure breaker ring (Worthington Compressor Co.

Service Manual).

of the ring, and it would dangle. The most important function of

breakers in compressor service is to retard backflow from the pack-

ing case toward the cylinder on the intake stroke.

4. Radial, Tangent, and Back-Up Set

This is the basic sealing unit used in higher pressure lubricated and

non-lubricated compressors, where Teflon (PTFE) ring material is

used and is a combination of three rings in one cup (see Figure 3-41).

It is made up of one radial and one tangential packing ring, with

one radial-cut back-up ring completing the combination. The radial

packing ring is installed in the groove on the pressure side toward

the cylinder. The tangential-cut ring is installed between the radially

cut packing ring and the back-up ring.

The back-up ring may be metallic or Teflon and is bored .003"

per inch of outside diameter larger than the piston rod. It has butted

ends with zero gap clearance and does not grip the rod under pres-

sure loading. Its function is to prevent extrusion of the Teflon mem-

ber of the packing rings and to conduct heat away from the rod sur-

face by light contact with the rod.