Page 212 - Reciprocating Compressors Operation Maintenance

P. 212

198 Reciprocating Compressors: Operation and Maintenance

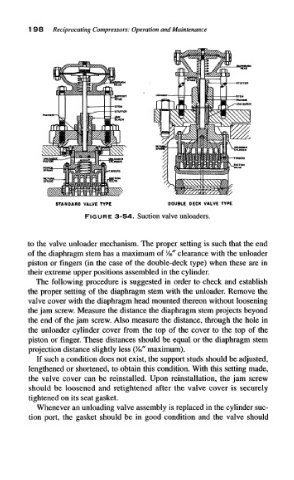

STANDARD VALVE TYPE DOUBLE DECK VALVE TYPE

FIGURE 3-54. Suction valve uriloaders.

to the valve unloader mechanism. The proper setting is such that the end

of the diaphragm stem has a maximum of 14" clearance with the unloader

piston or fingers (in the case of the double-deck type) when these are in

their extreme upper positions assembled in the cylinder.

The following procedure is suggested in order to check and establish

the proper setting of the diaphragm stem with the unloader. Remove the

valve cover with the diaphragm head mounted thereon without loosening

the jam screw. Measure the distance the diaphragm stem projects beyond

the end of the jam screw. Also measure the distance, through the hole in

the unloader cylinder cover from the top of the cover to the top of the

piston or finger. These distances should be equal or the diaphragm stem

projection distance slightly less (Me" maximum).

If such a condition does not exist, the support studs should be adjusted,

lengthened or shortened, to obtain this condition. With this setting made,

the valve cover can be reinstalled. Upon reinstallation, the jam screw

should be loosened and retightened after the valve cover is securely

tightened on its seat gasket.

Whenever an unloading valve assembly is replaced in the cylinder suc-

tion port, the gasket should be in good condition and the valve should