Page 245 - Reciprocating Compressors Operation Maintenance

P. 245

23O Reciprocating Compressors: Operation and Maintenance

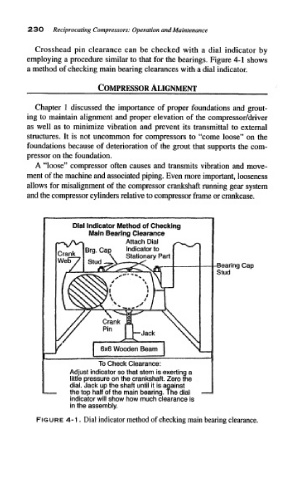

Crosshead pin clearance can be checked with a dial indicator by

employing a procedure similar to that for the bearings. Figure 4-1 shows

a method of checking main bearing clearances with a dial indicator.

^ COMPRESSOR ALIGNMENT

Chapter 1 discussed the importance of proper foundations and grout-

ing to maintain alignment and proper elevation of the compressor/driver

as well as to minimize vibration and prevent its transmittal to external

structures. It is not uncommon for compressors to "come loose" on the

foundations because of deterioration of the grout that supports the com-

pressor on the foundation.

A "loose" compressor often causes and transmits vibration and move-

ment of the machine and associated piping. Even more important, looseness

allows for misalignment of the compressor crankshaft running gear system

and the compressor cylinders relative to compressor frame or crankcase.

Dial Indicator Method of Checking

Main Bearing Clearance

**-v/V-* Attach Dial s~^ ^

\f

^*~r

Crank Brg. Cap Indicator to

\ Stationary Part

C) nH X ^

/ "^^^^.ftrH -Bearing Cap

Stud

sS^v "" % % \

/ / $

//$>X>^/' » 1

\^ I /'

KN>OsXN?l

y

/ Crank fi i \

^

6x6 Wooden Beam \

/

-n

To Check Clearance: 1

Adjust indicator so that stem is exerting a

little pressure on the crankshaft. Zero the

dial. Jack up the shaft until it is against

the top half of the main bearing. The dial —

indicator will show how much clearance is

in the assembly.

FIGURE 4-1. Dial indicator method of checking main bearing clearance.