Page 242 - Reciprocating Compressors Operation Maintenance

P. 242

C H A P T E R 4

Overhaul and Repair of

Reciprocating Compressors

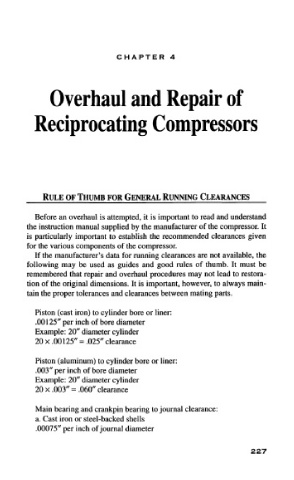

RULE OF THUMB FOR GENERAL RUNNING CLEARANCES

Before an overhaul is attempted, it is important to read and understand

the instruction manual supplied by the manufacturer of the compressor. It

is particularly important to establish the recommended clearances given

for the various components of the compressor.

If the manufacturer's data for running clearances are not available, the

following may be used as guides and good rules of thumb. It must be

remembered that repair and overhaul procedures may not lead to restora-

tion of the original dimensions. It is important, however, to always main-

tain the proper tolerances and clearances between mating parts.

Piston (cast iron) to cylinder bore or liner:

,00125" per inch of bore diameter

Example: 20" diameter cylinder

20 x .00125" = .025" clearance

Piston (aluminum) to cylinder bore or liner:

,003" per inch of bore diameter

Example: 20" diameter cylinder

20 x .003" = .060" clearance

Main bearing and crankpin bearing to journal clearance:

a. Cast iron or steel-backed shells

.00075" per inch of journal diameter

227