Page 253 - Reciprocating Compressors Operation Maintenance

P. 253

238 Reciprocating Compressors: Operation and Maintenance

within a system. In addition, maintenance procedures and repair meth-

ods, such as grouting, can be evaluated.

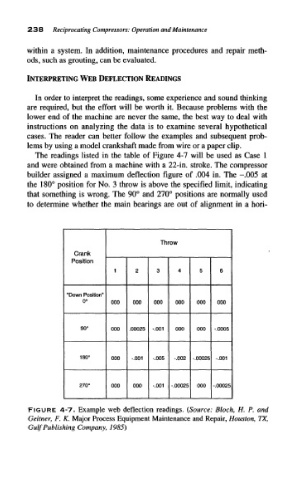

In order to interpret the readings, some experience and sound thinking

are required, but the effort will be worth it. Because problems with the

lower end of the machine are never the same, the best way to deal with

instructions on analyzing the data is to examine several hypothetical

cases. The reader can better follow the examples and subsequent prob-

lems by using a model crankshaft made from wire or a paper clip.

The readings listed in the table of Figure 4-7 will be used as Case 1

and were obtained from a machine with a 22-in. stroke. The compressor

builder assigned a maximum deflection figure of .004 in. The -.005 at

the 180° position for No. 3 throw is above the specified limit, indicating

that something is wrong. The 90° and 270° positions are normally used

to determine whether the main bearings are out of alignment in a hori-

Throw

Crank

Position

1 2 3 4 5 6

"Down Position"

0° 000 000 000 000 000 000

90° 000 .00025 -.001 000 000 -.0005

180° 000 -.001 -.005 -.002 -.00025 -.001

270° 000 000 -.001 -.00025 000 -.00025

FIGURE 4-7. Example web deflection readings. (Source: Block, H. P. and

Geitner, F. K. Major Process Equipment Maintenance and Repair, Houston, TX,

Gulf Publishing Company, 1985)