Page 379 - Reciprocating Compressors Operation Maintenance

P. 379

364 Reciprocating Compressors: Operation and Maintenance

FRAME VIBRATION MONITORING

The benefits of frame vibration monitoring are the prevention of cata-

strophic failure and the reduction of the amount of damage to a machine.

This is accomplished by detection of small changes in the case motion.

With modern 32-channel reciprocating compressor monitoring systems

and associated seismic transducers, companies such as Bently-Nevada

offer the user many advantages over the traditional, and often unreliable,

"g-switch" type of detector.

Bently-Nevada, one of a number of capable manufacturers of machin-

ery condition monitoring equipment, furnished an interesting case history.

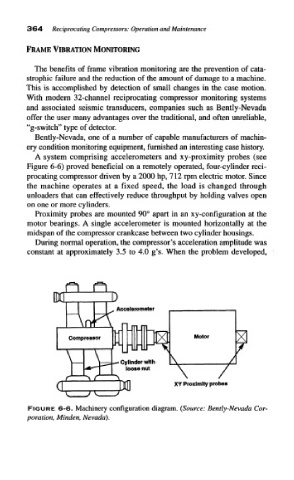

A system comprising accelerometers and xy-proximity probes (see

Figure 6-6) proved beneficial on a remotely operated, four-cylinder reci-

procating compressor driven by a 2000 hp, 712 rpm electric motor. Since

the machine operates at a fixed speed, the load is changed through

unloaders that can effectively reduce throughput by holding valves open

on one or more cylinders.

Proximity probes are mounted 90° apart in an xy-configuration at the

motor bearings. A single accelerometer is mounted horizontally at the

midspan of the compressor crankcase between two cylinder housings.

During normal operation, the compressor's acceleration amplitude was

constant at approximately 3.5 to 4.0 g's. When the problem developed,

FIGURE 6-6. Machinery configuration diagram. (Source: Bently-Nevada Cor-

poration, Minden, Nevada).