Page 58 - Reciprocating Compressors Operation Maintenance

P. 58

Design and Materials for Reciprocating Compressor Components 45

Bearing Pedestal

Crankshaft Connecting

Rod

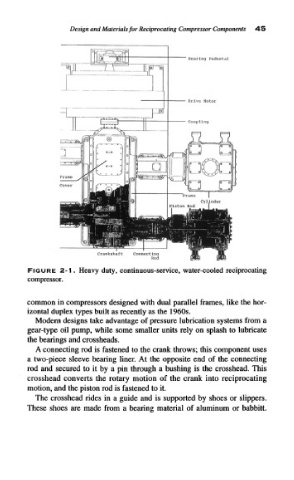

FIGURE 2-1. Heavy duty, continuous-service, water-cooled reciprocating

compressor.

common in compressors designed with dual parallel frames, like the hor-

izontal duplex types built as recently as the 1960s.

Modern designs take advantage of pressure lubrication systems from a

gear-type oil pump, while some smaller units rely on splash to lubricate

the bearings and crossheads.

A connecting rod is fastened to the crank throws; this component uses

a two-piece sleeve bearing liner. At the opposite end of the connecting

rod and secured to it by a pin through a bushing is the crosshead. This

crosshead converts the rotary motion of the crank into reciprocating

motion, and the piston rod is fastened to it.

The crosshead rides in a guide and is supported by shoes or slippers.

These shoes are made from a bearing material of aluminum or babbitt.