Page 60 - Reciprocating Compressors Operation Maintenance

P. 60

Design and Materials for Reciprocating Compressor Components 47

A knowledge of the materials used in the construction of the major

components of the heavy-duty water-cooled compressor will permit the

proper maintenance and repair of those components.

Frame or crankcase is a high-grade cast-iron casting similar to

ASTM class 40 or 50; it is designed with suitable supports or ribbing to

mount the compressor cylinders, crankshaft, and other running gear parts

and hold them in accurate alignment under the stresses imposed during

operation.

Crankshafts are made from carbon steel forgings or nodular iron

(ductile) castings. Most forgings are carbon steel conforming to AISI

1020, ASTM 668 for small shafts and AISI 1045, ASTM 668 class F for

large shafts. Nodular iron crankshafts conform to ASTM A-536 Grade

80-55-06. No hard surface treatment is used, and the shafts are not

dynamically balanced, unless they are used on compressors with rotative

speeds of 900 rpm and above.

Main bearings may be horizontally split shells made of steel or cast

iron, with a lining of babbitt. Some are made of aluminum without babbitt

or of a steel/bronze/babbitt tri-metal construction. The shells may have a

laminated shim placed between the halves to permit adjustment for wear.

On some smaller compressors, anti-friction roller bearings are used.

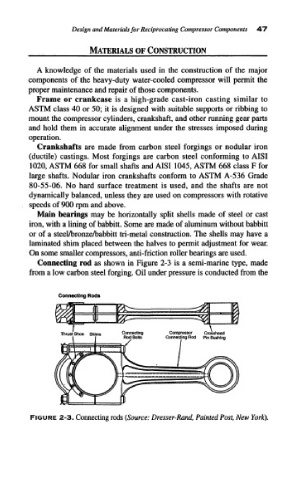

Connecting rod as shown in Figure 2-3 is a semi-marine type, made

from a low carbon steel forging. Oil under pressure is conducted from the

Connecting Rods

FIGURE 2-3. Connecting rods (Source: Dresser-Rand, Painted Post, New York).