Page 61 - Reciprocating Compressors Operation Maintenance

P. 61

48 Reciprocating Compressors: Operation and Maintenance

crankpins to the crosshead pin. Similar to the main bearing, crankpin

bearings are babbitt-lined steel or cast-iron shells. They may be shim-

adjustable or shimless. In other designs, bearings are made from alu-

minum, bronze, or tri-metal construction.

The crosshead pin bushings are bronze, aluminum or babbitt-lined on

steel/cast-iron backing.

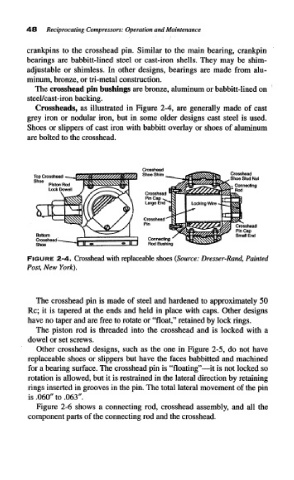

Crossheads, as illustrated in Figure 2-4, are generally made of cast

grey iron or nodular iron, but in some older designs cast steel is used.

Shoes or slippers of cast iron with babbitt overlay or shoes of aluminum

are bolted to the crosshead.

Top Crosshead

ShOS

Piston Rod

Lock Dowell

Crosshead

Pin Cap

Bottom I ^~~~~ i ' _ .. _ *~~*ffKfSSSlB!Vir~ SmattEnd

Crosshead—

Shoe

FIGURE 2-4. Crosshead with replaceable shoes (Source: Dresser-Rand, Painted

Post, New York).

The crosshead pin is made of steel and hardened to approximately 50

Re; it is tapered at the ends and held in place with caps. Other designs

have no taper and are free to rotate or "float," retained by lock rings.

The piston rod is threaded into the crosshead and is locked with a

dowel or set screws.

Other crosshead designs, such as the one in Figure 2-5, do not have

replaceable shoes or slippers but have the faces babbitted and machined

for a bearing surface. The crosshead pin is "floating"—it is not locked so

rotation is allowed, but it is restrained in the lateral direction by retaining

rings inserted in grooves in the pin. The total lateral movement of the pin

is .060" to .063".

Figure 2-6 shows a connecting rod, crosshead assembly, and all the

component parts of the connecting rod and the crosshead.