Page 125 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 125

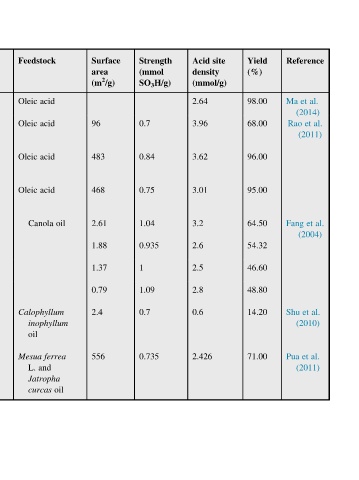

Reference al. et Ma (2014) al. et Rao (2011) al. et Fang (2004) al. et Shu (2010) al. et Pua (2011)

Yield (%) 98.00 68.00 96.00 95.00 64.50 54.32 46.60 48.80 14.20 71.00

site

Acid density (mmol/g) 2.64 3.96 3.62 3.01 3.2 2.6 2.5 2.8 0.6 2.426

Strength (mmol SO 3 H/g) 0.7 0.84 0.75 1.04 0.935 1 1.09 0.7 0.735

Surface area (m 2 /g) 96 483 468 2.61 1.88 1.37 0.79 2.4 556

oil ferrea oil

Feedstock acid Oleic acid Oleic acid Oleic acid Oleic Canola Calophyllum inophyllum oil Mesua and L. Jatropha curcas

S time (h) 4 1 1 1 5 5 15 15 5 1

S temp ( C) 333 3 5 3 5 3 5 150 150 150 150 150 3 5

agent. C time (h) 1 1 1 1 5 1

sulfonating C temp ( C) 573 500 500 500 527 527 527 527 400 500

different agent sulfuric sulfuric sulfuric sulfuric sulfuric acid C temp , carbonization temperature; C time , carbonization time; S temp , sulfonation temperature; S time , sulfonation time.

by Sulfonating Fuming acid Fuming acid Fuming acid Fuming acid Fuming acid p-Toluene sulfonic

preparation 4-BDS 4-BDS 4-BDS 4-BDS

Catalyst straw Jatropha seed curcas Paullinia seed pinnata Mesua L. ferrea seed char Hardwood char Hardwood char Hardwood char Hardwood Calophyllum inophyllum seed waste cake

4.2 Biomass Corn Deoiled Deoiled Deoiled Deoiled Oil

Table S. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10.