Page 132 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 132

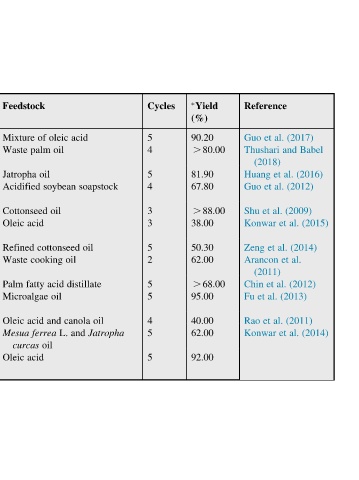

(2017) Babel and (2016) al. (2012) (2009) (2015) al. (2014) al. al. et (2012) (2013) (2011) (2014) al.

Reference al. et Guo Thushari (2018) et Huang al. et Guo al. et Shu et Konwar et Zeng Arancon (2011) al. et Chin al. et Fu al. et Rao et Konwar

Yield (%) 90.20 . 80.00 81.90 67.80 . 88.00 38.00 50.30 62.00 . 68.00 95.00 40.00 62.00 92.00

Cycles 5 4 5 4 3 3 5 2 5 5 4 5 5

soapstock oil Jatropha

acid oil oil distillate canola and

oleic oil oil soybean oil cottonseed cooking acid oil and L. ferrea oil

Feedstock of Mixture palm Waste Jatropha Acidified Cottonseed acid Oleic Refined Waste fatty Palm Microalgae acid Oleic Mesua curcas acid Oleic

method process process sulfonation sulfonation process process process activation process activation activation reaction.

Preparation Thermal process In-situ Solvothermal Direct Direct Hydrothermal process Thermal Thermal Thermal In-situ process Thermal Chemical 4-BDS Chemical 4-BDS T, transesterification

reaction;

L.

studies. meal coconut lignin sorbifolia hulls asphalt oil ferrea Mesua bagasse residue meal canola waste L. esterification

reusability Biomass husk Rice Deoiled De-alkaline Xanthoceras bunch Vegetable Deoiled seed shell Peanut Corncob Sugarcane Microalgae Deoiled cake ferrea Mesua E, cycle; last

Catalyst E&T E&T Oil the at

4.3 E/T E T E E T E T E E E E (%), Yield

Table S. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 Yield