Page 234 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 234

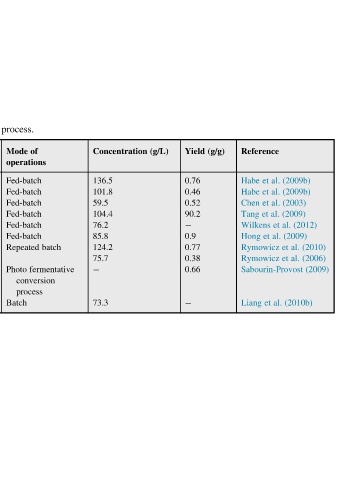

(2009b) (2009b) (2003) (2009) (2012) al. (2009) (2010) al. et (2006) al. et (2009) (2010b)

Reference al. et Habe al. et Habe al. et Chen al. et Tang et Wilkens al. et Hong Rymowicz Rymowicz Sabourin-Provost al. et Liang

(g/g)

Yield 0.76 0.46 0.52 90.2 0.9 0.77 0.38 0.66

(g/L)

Concentration 136.5 101.8 59.5 104.4 76.2 85.8 124.2 75.7 73.3

batch fermentative

process. of Mode operations Fed-batch Fed-batch Fed-batch Fed-batch Fed-batch Fed-batch Repeated Photo conversion process Batch

fermentation Substrate Glycerol Glycerol Glycerol Glycerol glycerol Glycerol Glycerol Glycerol Glycerol Glycerol

microbial Crude

through NBRC103465 NBRC16470 2026 DSM AKR102a strain palustris SR21

glycerol frateurii tropicalis pneumoniae K12 butyricum limacinum

from Microorganism Gluconobacter coli AC-521 lipolytica K-1 lipolytica Rhodopseudomonas Schizochytrium

produced Acetobacter Klebsiella Escherichia Clostridium coli E. Yarrowia Y.

Product

9.2 acid 1,3-Propanediol acid acid

Table Product Glyceric Lactic Citric Hydrogen Lipid