Page 338 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 338

and (2016) al. (2009) al. (2015a) (2010) al.

Omar Amin et (1980) Garcıa-Cubero al. al. et (2012) et (2013) al. al. al. et (2015) (1984) and Molinier (1988) et (2013)

Ref. Wan Binder ´ et Kaur Travaini et Li et Lee Ueda Neely Vidal Ben’ko

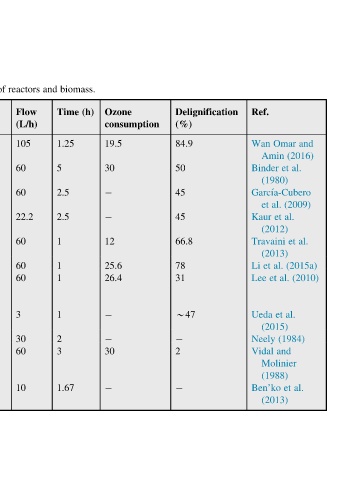

Delignification (%) 84.9 50 45 45 66.8 78 31 B47 2

Ozone consumption 19.5 30 12 25.6 26.4 30

biomass. (h) Time 1.25 1.67

and 5 2.5 2.5 1 1 1 1 2 3

reactors Flow (L/h) 105 60 60 22.2 60 60 60 3 30 60 10

of

types Ozone (%) conc.

different n.a 0.44 2.7 2.1 3.44 2.8 25 6 3.37 1.63 2.8

in Particle (mm) , 0.053

pretreatment size (%) 0.8 , 0.2 3 5 2 3 5 , 2 , 5 0.106 2 0.6 1

ozonolysis Moisture content 40 95 60 35 80 60 30 40 50 30 40

of

parameters Reactor design Semibatch Batch Fixed-bed Fixed-bed Fixed-bed Fixed-bed Rotatory rotatory Cylindrical Fixed-bed Fixed-bed

Process fronds

14.2 material palm straw straw stalks bagasse stover Bermuda culture oak sawdust wood

Table Raw Oil Wheat Rye Cotton Sugarcane Maize Coastal grass Spent media Red Poplar Aspen chips