Page 364 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 364

(2017) (2018) (2017) (2017) (2017) al. et (2017) al.

al. al. Abouloula (2018) (2015) al. al. al. et

et et al. et et et Rachtanapun (2012)

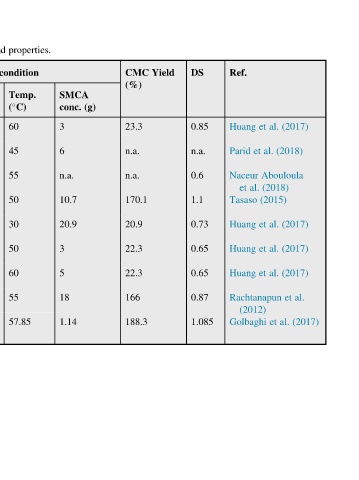

Ref. Huang Parid Naceur et Tasaso Huang Huang Huang Golbaghi

DS 0.85 n.a. 0.6 1.1 0.73 0.65 0.65 0.87 1.085

Yield

CMC (%) 23.3 n.a. n.a. 170.1 20.9 22.3 22.3 166 188.3

(g)

SMCA conc. 3 6 n.a. 10.7 20.9 3 5 18 1.14

properties. condition Temp. ( C) 60 45 55 50 30 50 60 55 57.85

and

conditions Reaction Time (h) 3 3 3 3 3 3 3 3 4.01

process conc. mL g/100

optimal NaOH (wt.%) 20 30 30 52 30 40 30 30 28.4

(CMC) pulping monochloroacetate.

cellulose process sodium acid, sodium acid, hydroxide, chloride oxidation sodium acid, sodium acid, sodium acid, oxidation explosion sodium

Carboxymethyl Pretreatment Acetic chlorite Acetic chlorite Sodium sodium Wet Acetic chlorite Acetic chlorite Acetic chlorite Wet Steam SMCA, substitution;

14.7 tea fruit fruit palm kernel duckweed rind bagasse of Degree

Table Raw material Spent leaves Empty bunch Empty bunch Oil fronds Palm cake Coconut fibers Dried Durian Sugarcane DS,